China PP Corrugated Sheet Machine Manufacturer, Supplier, Factory

Our goal will be to offer premium quality items at competitive price ranges, and top-notch support to consumers around the planet. We are ISO9001, CE, and GS certified and strictly adhere to their high quality specifications for PP Corrugated Sheet Machine,PP Sheet Extruder Machine,PP Hollow Sheet Machine,PP Sheet Making Machine,PP Sheet Machine, Only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment.

PP Corrugated Sheet Machine, We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and solutions and perfect service . We also warmly welcome customers to visit our company and purchase our products.

Hot Products

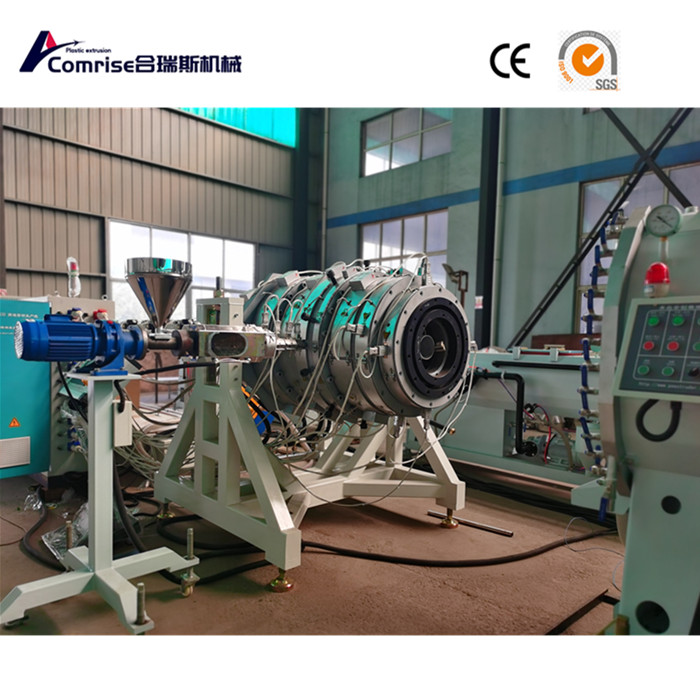

Steel Reinforced Polyethylene Pipe Machine

Comrise is China steel reinforced polyethylene pipe machine supplier. At COMRISE, we have a simple philosophy: to provide our customers with the best machinery possible. We believe that every customer deserves the best quality machinery, and we strive to achieve this goal with every machine we make. Our mission is to help our customers improve their manufacturing processes, increase efficiency, and reduce production costs by providing them with the best machinery available in the market.Pe Spiral Winding Pipe Machine

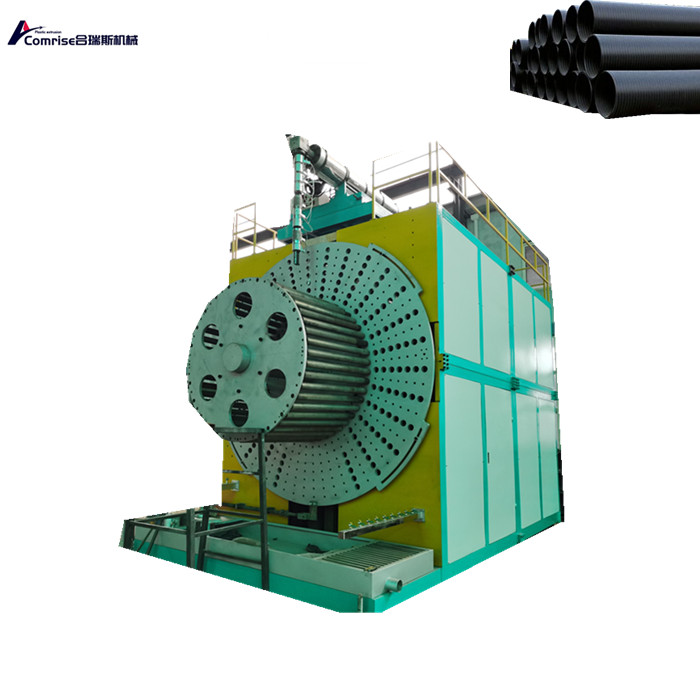

COMRISE specialize in providing advanced pe spiral winding pipe machine machinery for underground sewage construction or building usage. Comrise pe spiral winding pipe machine are used to create a variety of pipe types for different applications, such as hollow wall spiral winding, inner rib spiral winding, smooth wall winding, double plastic winding, and plastic insert steel winding. Comrise take pride in our expertise when it comes to larger diameter pipe machines, as it requires not only specialized machinery but also highly skilled professionals to operate them.HDPE Large-Diameter Hollowness Wall Winding Pipe Machine

COMRISE High quality HDPE large-diameter hollowness wall winding pipe machine supplierr is offered by China manufacturer Comrise, which can produce pipe size range from Ø200-3000mm. We are one of the drafters of nation standard for hollow wall winding pipe. PE hollow wall winding pipe is mainly used for water drainage, same as double wall corrugated pipe. Compared with double wall corrugated pipe, it have advantages of low machine investment cost and larger pipe diameter. With different design of profile tube our machinery can produce pipes of different ring stiffness that adapt to different conditions and fields.Co Extrusion HDPE Pipe Production Line

Comrise is a leading manufacture for ABC Three Layer Co Extrusion HDPE Pipe Production Line in China. Comrise specialized in the manufacturing of high-quality plastic extrusion equipment, including plastic pipe, sheet and profile equipment, as well as plastic winding pipe equipment. With over 20 years of experience in the industry, COMRISE has a mature and professional team of engineers and customer service representatives. Comrise company dedicate to provide top-of-the-line products and services, with strict quality control measures, We look forward to working with you to move the plastic extrusion equipment industry forward.EVA Vacuum Hose Pipe Machine

Comrise Machinery is a professional machine manufacture in China for EVA Vacuum Hose Pipe Machine and other plastic pipe and sheet machine manufacture. Customized EVA Vacuum Hose Pipe Machine is with mature technology, with PLC automatically control, easy operation and stable production. The newest EVA Vacuum Hose Pipe Machine can make single color or double color Eva cleaning pipe as per customer detail requirements. If you want more information please contact us. Cell: +8613780696467. Email: sales@qdcomrise.comComposite Decking Profile Machine

Comrise Machinery is a professional manufacturer of PE WPC wood-plastic composite decking profile machines. We offer comprehensive solutions, including all processes from raw materials to finished products, to produce high-quality, environmentally friendly, and durable composite flooring. Comrise PE WPC wood-plastic composite decking profile machine use advanced technology to achieve high productivity and efficiency while keeping operating costs low. Comrise also provide comprehensive technical support and after-sales service, ensuring that our clients can operate our equipment with ease and minimize downtime. Comrsie PE WPC wood-plastic composite decking profile machines can be customized to meet the specific needs of our clients. Comrise are known for our high-quality products and services, ensuring the complete satisfaction of our clients. If you're searching for a reliable and efficient manufacturer of PE WPC wood-plastic composite decking profile machines, look no further than Comrise Machinery.