Plastic Pipe Machine

- View as

Three layer hdpe co extrusion pipe machine line

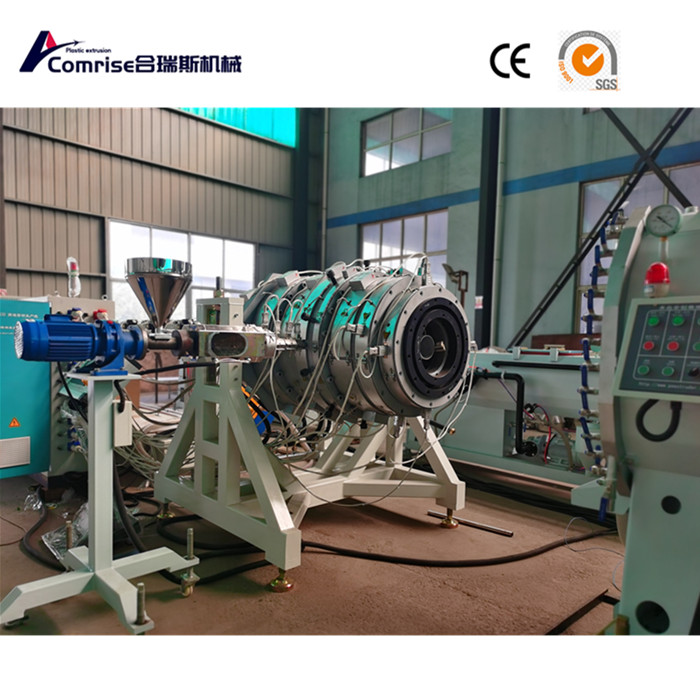

Comrise PE pipes are commonly used for urban water supply, transportation of natural gas and gas, food and chemical industries, transportation of ore and mud, replacement of cement pipes, cast iron pipes, and steel pipes.china pipe factory 315-630mm three layer hdpe co extrusion pipe machine line price good. Ppr pipes are widely used in the fields of building water supply and drainage, urban and rural water supply and drainage, urban gas, electricity, and fiber optic cable sheaths, as well as in the construction, municipal, industrial and agricultural sectors, industrial fluid transportation, and agricultural irrigation.

Read MoreSend InquirySingle wall corrugated pipe production machine

High-speed Plastic Corrugated Pipe Machine comrise plastic single-wall corrugated pipe production line developed by our company adopts gears to run moulds and templates so as to realize water circulating cooling and air cooling of the products, which ensures high-speed molding,Single wall corrugated pipe production machine even corrugation, smooth inner and outer pipe wall.Comrise is an excellent supplier and manufacturer of pipe machinery in China. These corrugated pipes are especially used as wires of the up-market cars.

Read MoreSend InquiryDouble Wall Corrugated Pipe Extruder Machine

COMRISE Good qulaity HDPE double wall corrugated DWC pipe machine adopts extruding and forming process, it has the featuresof reliable quality and high efficiency.Double Wall Corrugated Pipe Extruder Machine 40-160mm,Compared with other plastic pipe wall structure ,double wall corrugated pipe has excellent wall structure design,its low weight reach the lower production cost and improve the market competitiveness.supplier good qulaity and price The pipe is widely used in various field instead of concrete pipe and iron pipes,because it has excellent features such as:easy connected and accessories installed,and quality reliable.

Read MoreSend InquiryPVC Pipe Production Line machine

Comrise PVC pipe extrusion line includes conical twin screw extruder, spiral die head, vacuum tank, water tank, haul-off, no-dust cutter or planetary cutter, belling machine with O-ring sockets or rectangular sockets or U types of sockets.this machine supplier Our PVC pipe production line machine can make pipes ranging from 16-630mm PVC Pipe Machine, wall thickness range of 1-30mm.

Read MoreSend InquiryHDPE Pipe Production Line Machine

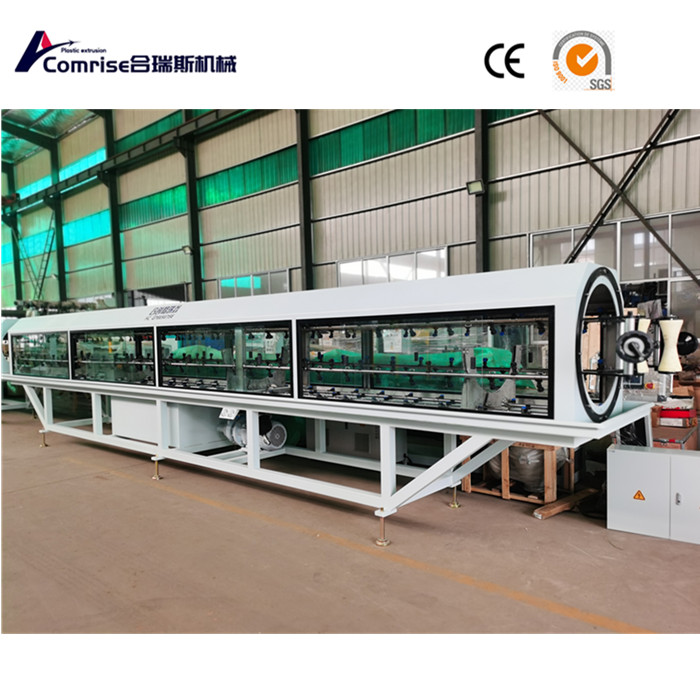

COMRISE HDPE pipe production line machine is mainly used for producing water supply and drainage pipes in agriculture, construction and other fields.315-630mm HDPE Pipe Production Line supplier This machine consists of an extruder, a mold, a vacuum calibration tank, and a traction device. Cutting unit, stacker crane and other single units The screw extruder and traction device are equipped with well-known air conditioning variable frequency speed regulation devices, and the vacuum pump and water pump are both from well-known brands. Traction devices include two claw, three claw, four claw, six claw, eight claw, ten claw, twelve claw, etc. Dust free cutting machines, saw blade cutting machines, or planetary cutting machines can be used, and the performance of the unit is reliable.

Read MoreSend InquiryHigh Speed Single Wall Corrugated Pipe Machine Line

COMRISE plastic single-walled corrugated pipe production line is carefully developed by comrise.High Speed Single Wall Corrugated Pipe Machine Line, Through gear transmission molds and water-cooled forming machines in the water tank, the pipes produced have fast forming speed, uniform corrugated shape, and smooth inner and outer walls. The production speed is 8-15 meters per minute.

Read MoreSend Inquiry