Plastic Pipe Machine

- View as

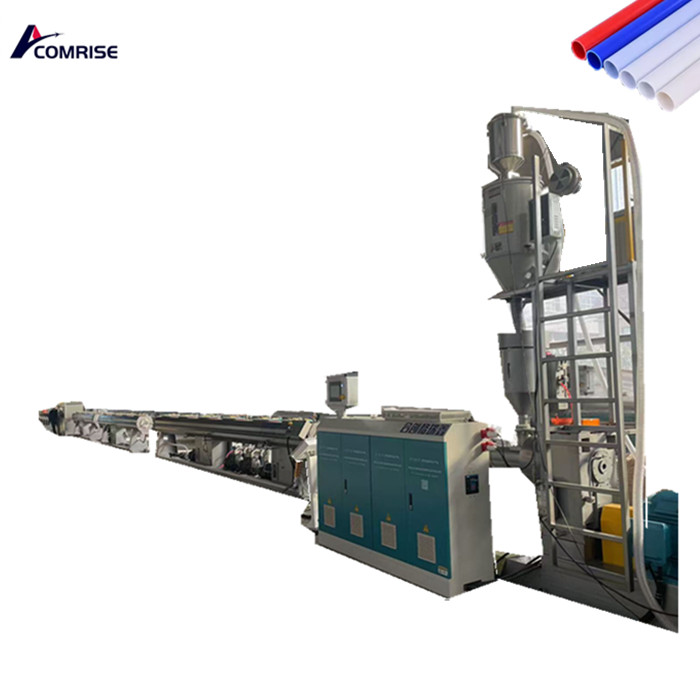

HDPE pipe extrusion line

Comrise is a leading China 110-315 HDPE pipe extrusion line. Wrap multiple layers or layers of high-strength fibers such as glass fiber and polyester fiber onto existing pure PE pipes to make the pipes work,110-315 HDPE pipe extrusion line. Pressure increased to 4Mpa. The entire production line is automatically controlled by PLC from material replacement to stacking, ensuring reliability high, easy to maintain. The outstanding feature of this production line is that it can not only produce pure PE pipes that meet international standards. It can also produce steel wire reinforced composite plastic pipes.

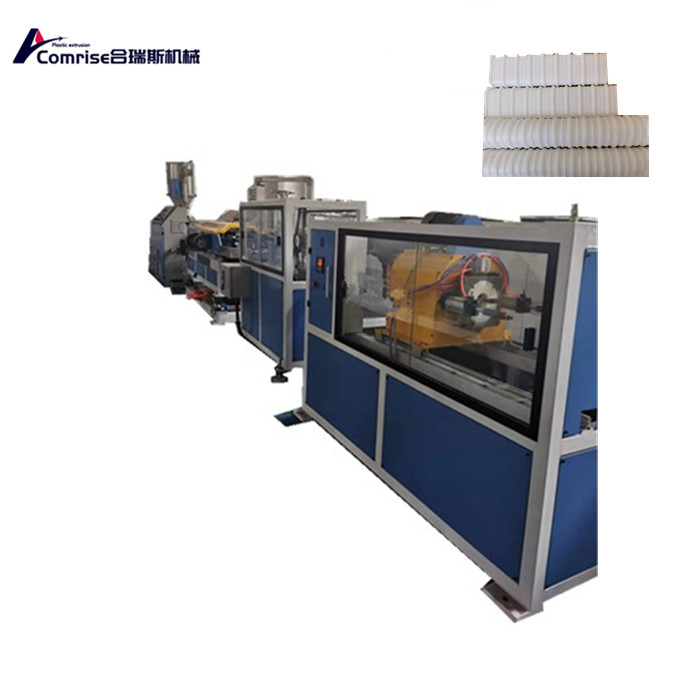

Read MoreSend InquiryDouble Wall Corrugated Pipe Machine Line

COMRISE Plastic corrugated pipes are widely used in our daily lives, including threading pipes, drainage pipes, pipelines, hookah pipes, shrink tubing, Double Wall Corrugated Pipe Machine Line comrise manufature etc. Plastic corrugated pipes have many advantages: 1. Compared with sheet pipes, corrugated pipes are lighter in weight, save materials, have lower energy consumption, and are cheaper in price; 2. Smooth corrugated pipes on the inner wall can reduce the flow resistance of liquids in the pipeline and improve transportation capacity; 3. It has good chemical corrosion resistance and can resist the action of alkali in soil.We are manufacturers and suppliers from China

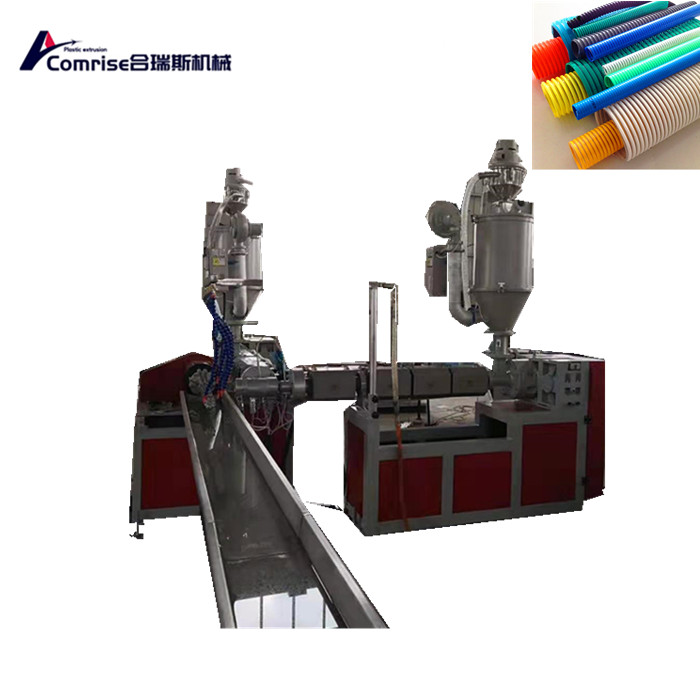

Read MoreSend InquiryHDPE Pipe Production Machine Line

COMRISE extrusion HDPE Pipe Production Machine Line can be used to produce PE pipes of different diameters, with excellent rigidity and flexibility, heat resistance, aging resistance, high mechanical strength, environmental stress cracking resistance, creep deformation resistance, thermal linkage, china factory etc. Therefore, this pipeline production line is the preferred choice for gas, water, and agricultural irrigation pipeline systems between urban and rural areas

Read MoreSend InquiryPE Bridge Prestressed Carbon Spiral Corrugated Pipe Machine

COMRISE The special separated mixing screw and standard designed mold have a spiral structure and reasonable channels, PE Bridge Prestressed Carbon Spiral Corrugated Pipe Machine supplier,suitable for producing pipes with smooth inner and outer surfaces. The spiral distribution method, different bodies, and large flow space ensure that the melted material has sufficient residence time. The optimal low melting temperature results in low internal stress in the pipeline and smooth inner and outer surfaces. Unique sizing cooling method, capable of producing pipes with a range of 50-200 millimeters, with a production speed of up to 0.6-1.5 meters per minute

Read MoreSend InquiryPVC Fiber Reinforced Soft Pipe Extrusion Line

COMRISE PVC Fiber Reinforced Soft Pipe Extrusion Line is designed to produce PVC soft spiral reinforced pipe, which is widely used in industry , agriculture , architecture , irrigation market and so on.We are china factory PVC Fiber Reinforced Soft Pipe Extrusion Line consists of two sets single screw plastic extruders, mould, forming machine,cooling water tank, rotatory haul off machine and winder.

Read MoreSend InquiryPVC steel wire pipe production machine

COMRISE PVC steel wire pipe production machine is designed specifically for manufacturing high-quality steel wire reinforced spiral corrugated pipes we manufacture it. The extrusion system includes a two-stage extrusion system, namely a steel coating extrusion system and a spiral forming extrusion system.chian top plastic machine factory

Read MoreSend Inquiry