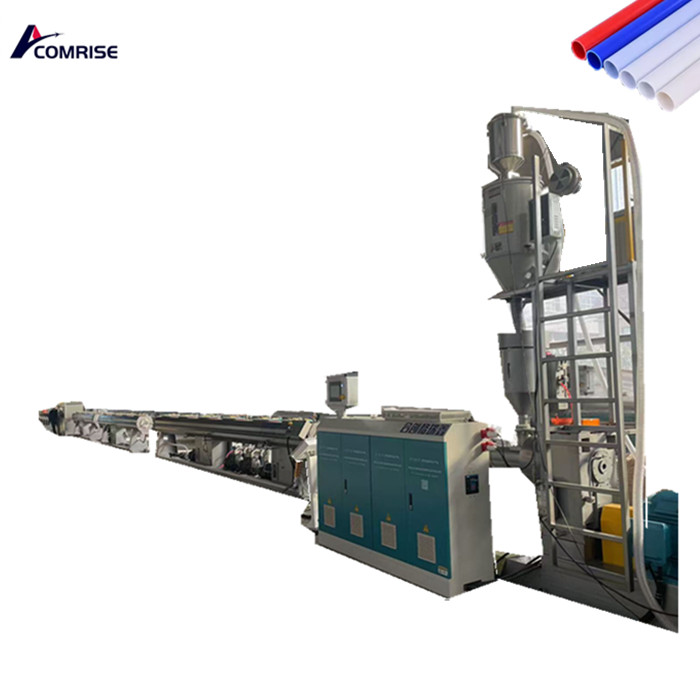

HDPE pipe extrusion line

Send Inquiry

The HDPE pipe extrusion line is mainly used to manufacture PE, HDPE, LDPE and various pipe diameters and wall thicknesses, such as agricultural and construction pipelines, water supply and drainage, etc.

The HDPE pipe extrusion line consists of a single screw extruder, vacuum calibrator, tractor, cutting machine, and self dumping rack we manufacture

3. PE pipe extruder production line: DN (mm): 16mm-110mm Thickness: 2.0-10.2mm Standards: ISO9001, GB, DIN Working pressure: 0.6MPa-1.6MPa.

4. Application: PE pipes are widely used in many fields, such as smoking, water and tobacco pipe areas, automotive lines, electric threading pipes, machine tool circuits, lamp protection pipes, air ducts, and washing machines

Plastic extruder

1.World famous brand electrical component such as Siemens, ABB etc .

2.High torque gearbox with adopts NSK bearing;

3.Bimetallic screw and barrel;

4.Intelligent PLC controlling system with human-friendly interface.

Mould

1.Material of mold body is Steel 45# ,harden treated and polished.

2.Material of inner mould parts is 40Cr.

3.The material of calibration bushing is Stannum bronze.

4.The diameter can be customized.

Vaccum calibration water tank:

1.Calibrating the pipe outer diameter and cooling pipe.

2.The material of water tank is stainless steel 304.

Hauling off machine

1.Function :haul off PE pipe stably and synchronal with extruder speed.

2.Clamping mode is pneumatically.

3.speed adjusting mode is frequency conversion.

cutter machine

1.Function:cut PE pipe in fixed length.

2.Cutting type:automatic meter counting cutter.

The HDPE pipe extrusion line single screw extruder designed specifically for PE particle extrusion can also be combined with PP PE PC pipe production lines and PP PE PC profile production lines.

We produce single screw extruders as well as high-speed and efficient single screw extruders china factory

This unit has advanced design, high output, good plasticization, and low energy consumption.

The characteristics of involute gear transmission are low noise, smooth operation, high load-bearing capacity, and long service life.

The screw structure of a single screw extruder can also be redesigned according to the customer's detailed raw materials and usage.

GET A QUOTATION NOW