Corrugated Pipe Machine

- View as

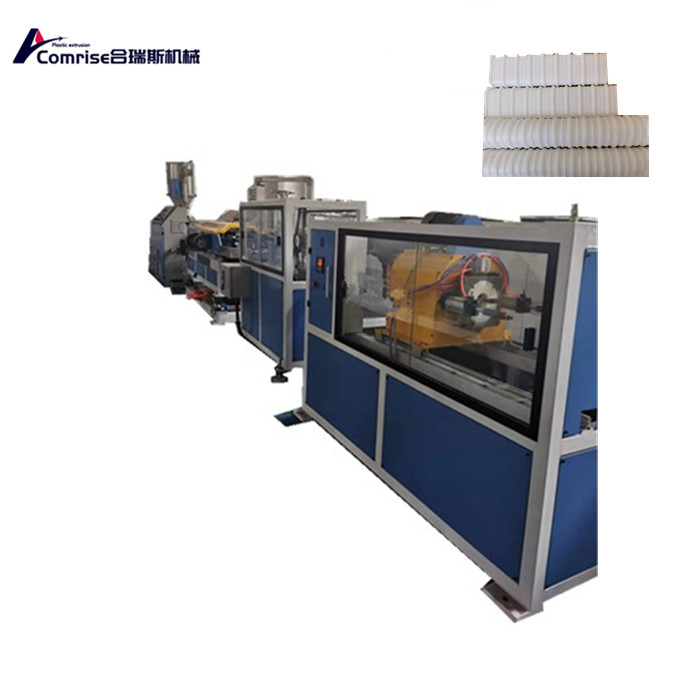

Double Wall Corrugated Pipe Machine Line

COMRISE Plastic corrugated pipes are widely used in our daily lives, including threading pipes, drainage pipes, pipelines, hookah pipes, shrink tubing, Double Wall Corrugated Pipe Machine Line comrise manufature etc. Plastic corrugated pipes have many advantages: 1. Compared with sheet pipes, corrugated pipes are lighter in weight, save materials, have lower energy consumption, and are cheaper in price; 2. Smooth corrugated pipes on the inner wall can reduce the flow resistance of liquids in the pipeline and improve transportation capacity; 3. It has good chemical corrosion resistance and can resist the action of alkali in soil.We are manufacturers and suppliers from China

Read MoreSend InquiryPE Bridge Prestressed Carbon Spiral Corrugated Pipe Machine

COMRISE The special separated mixing screw and standard designed mold have a spiral structure and reasonable channels, PE Bridge Prestressed Carbon Spiral Corrugated Pipe Machine supplier,suitable for producing pipes with smooth inner and outer surfaces. The spiral distribution method, different bodies, and large flow space ensure that the melted material has sufficient residence time. The optimal low melting temperature results in low internal stress in the pipeline and smooth inner and outer surfaces. Unique sizing cooling method, capable of producing pipes with a range of 50-200 millimeters, with a production speed of up to 0.6-1.5 meters per minute

Read MoreSend InquiryHigh speed single wall corrugated pipe machine

The COMRISE series plastic High speed single wall corrugated pipe machine is carefully developed by our company. Through gear transmission molds and water-cooled forming machines in the water tank, the produced pipes are formed quickly, with uniform corrugated shapes and smooth inner and outer walls. The production speed is 8-15 meters per minute.

Read MoreSend InquiryDouble Wall Corrugated Pipe Production machine

Comrise china factory supply Double Wall Corrugated Pipe Production machine 40-200mm Double Wall Corrugated Pipe machine 1. The host adopts a dedicated high-efficiency screw designed specifically for high-density polyethylene (HDPE), which has the characteristics of stable performance and high efficiency. This machine is equipped with two independent extruders, which can be used for practical applications Currently, different materials and colors are used for the inner and outer layers. 2. The composite extrusion mold adopts a special spiral structure to achieve uniform wall thickness and stable production. 3. The corrugated forming system combines water and air cooling to ensure high production speed.

Read MoreSend InquirySingle Wall Corrugated Pipe Machine Line

Comrise china factory PVC PE single wall corrugated pipe machine line/extrusion production line adopts extrusion molding technology, which has the characteristics of reliable quality and high efficiency. Compared with other plastic pipe wall structures, double walled corrugated pipes have excellent wall properties The structural design, with its low weight, achieves lower production costs and improves market competitiveness. It is widely used in various fields to replace concrete pipes and iron pipes because of its excellent features, such as easy connection and installation of accessories, and reliable quality

Read MoreSend InquiryGood Qulaity Double Wall Corrugated Pipe Machine

QINGDAO COMRISE MACHINERY main production line including high-efficiency PE water supply pipe production line, PE large-diameter hollow-wall winding pipe production line, Good Qulaity Double Wall Corrugated Pipe Machine, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line, the plastic coated corrugated pipe production line, PE black jacket insulation pipe production line and PE sheet/board production line. HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.

Read MoreSend Inquiry