China Single Wall Corrugation Plant Manufacturer, Supplier, Factory

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for Single Wall Corrugation Plant,Single wall corrugated pipe machine,Plastic Single Wall Corrugated Pipe Making Machine,Corrugated Pipe Machine,Corrugated Pipe Extruder, We sincerely welcome buddies to negotiate business enterprise and start cooperation with us. We hope to join hands with good friends in different industries to produce a brilliant long term.

Single Wall Corrugation Plant, We severely promise that we give all the customers with the best quality products and solutions, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

Hot Products

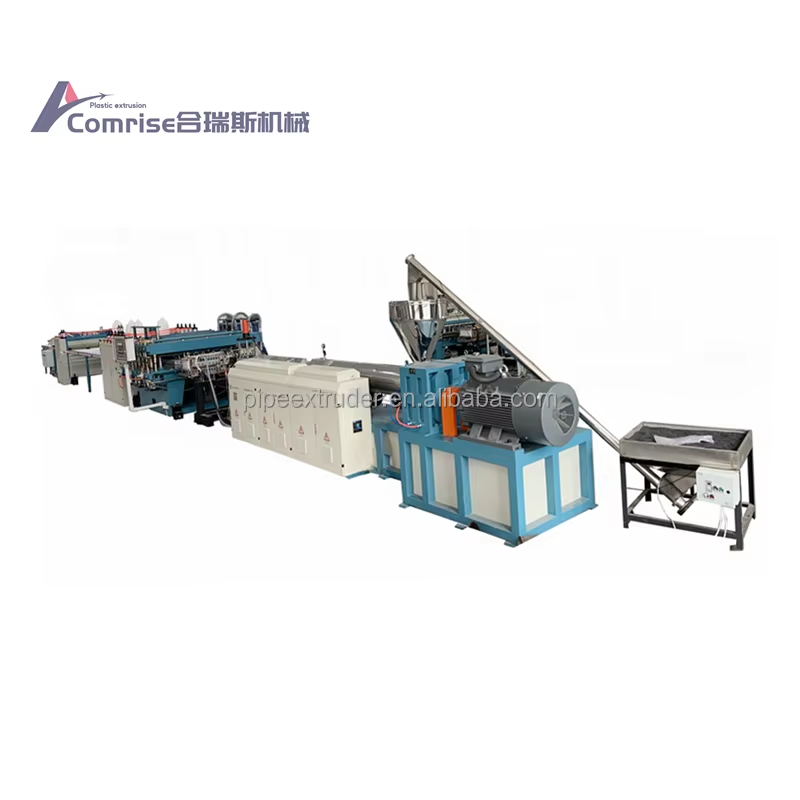

Plastic Sheet And Profile production Line

COEMRISE The board/sheet extrusion production line is a state-of-the-art manufacturing system designed to produce various plastic boards and sheets with excellent surface quality and dimensional stability. Plastic Pipe Sheet And Profile production Line,This production line supplier is very suitable for producing materials for various industries, including construction, packaging, automotive, and signage. Plastic Sheet And Profile production LineThe advanced technology of this production line ensures high precision and efficiency in producing standard and customized sheet products, including PVC, PS, PP, PE, and other thermoplastic materialsFlexible Corrugated Hose Extrusion Machine for Cable Protection

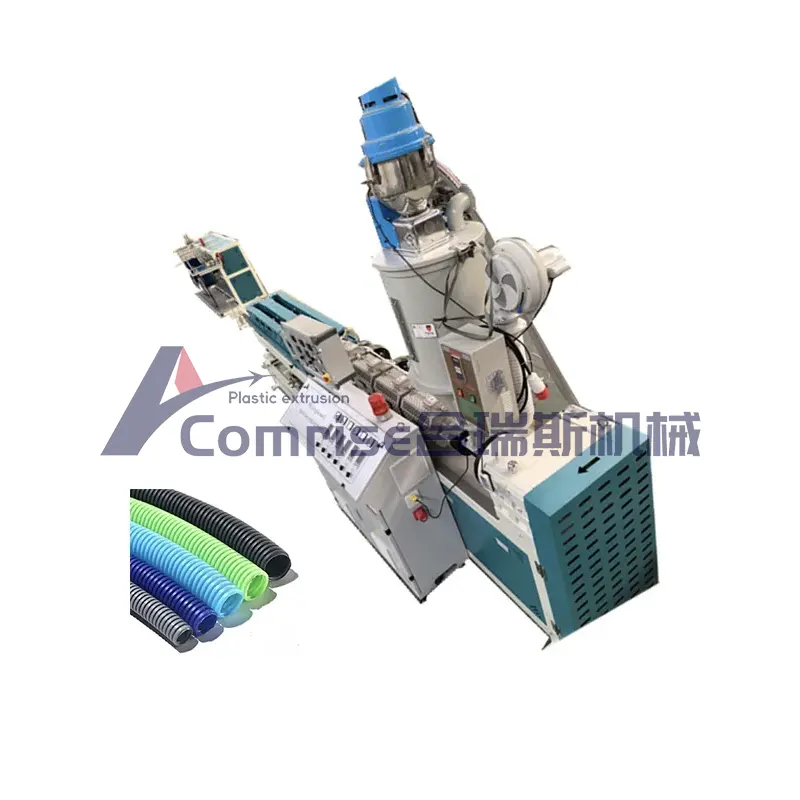

China factory comrise machinery has a range of flexible corrugated hose extrusion machine for cable protection that manufacture single wall corrugated pipes. These pipes provide efficient protection to cables and electrical wires while ensuring maximum safety. The flexible corrugated hose extrusion machine for cable protection supplied by Chinese manufacture Comrise Machinery are designed to produce pipes of different sizes and shapes, ensuring maximum flexibility.HDPE Pipe Production Line Machine

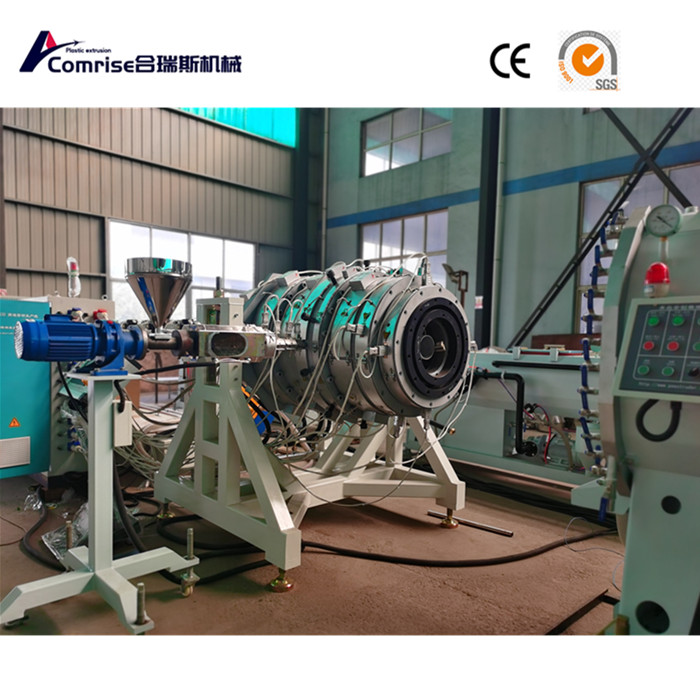

COMRISE HDPE pipe production line machine is mainly used for producing water supply and drainage pipes in agriculture, construction and other fields.315-630mm HDPE Pipe Production Line supplier This machine consists of an extruder, a mold, a vacuum calibration tank, and a traction device. Cutting unit, stacker crane and other single units The screw extruder and traction device are equipped with well-known air conditioning variable frequency speed regulation devices, and the vacuum pump and water pump are both from well-known brands. Traction devices include two claw, three claw, four claw, six claw, eight claw, ten claw, twelve claw, etc. Dust free cutting machines, saw blade cutting machines, or planetary cutting machines can be used, and the performance of the unit is reliable.HDPE Heat Insulation Pipe Extrusion Machine

Comrise company specializes in the production of high-quality plastic machinery that caters to a wide range of applications. We have a wide range of machines in our inventory, including HDPE water pipe machines, HDPE heat insulation pipe extrusion machines, PVC pipe machines, plastic sheet machines, and plastic board machines.

Whether you are a plumber, contractor, or manufacturer, Comrise has the perfect solution for your water transportation and insulation needs. Comrise hdpe heat insulation pipe extrusion machines are designed to be easy to use, efficient, and reliable, giving you the confidence you need to get the job done right the first time. So why settle for anything less? Choose Comrise for all your pipe welding and insulation needs.PU Foam Injection Machine for Insulated Pipe

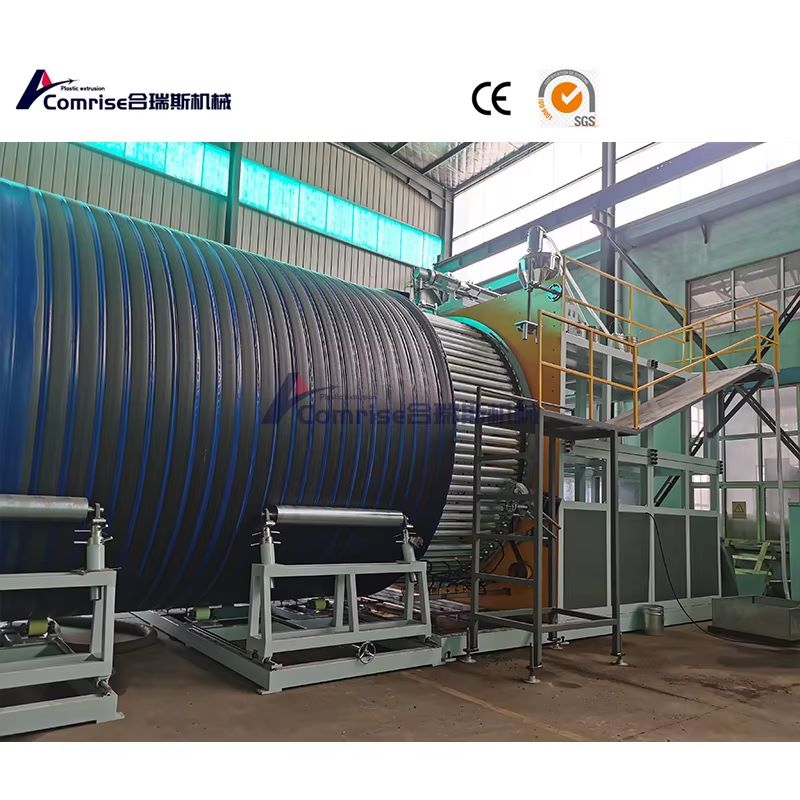

Comrise take pride in their products, and that is why they have invested in advanced technology and machinery to manufacture pu foam injection machine for insulated pipe. Their pu foam injection machines for insulated pipe are built to last and are engineered to meet the needs of diverse industries.Hollow Wall Winding Pipe Machinery

Comrise factory HDPE Hollow wall winding pipe machinery has been successfully used as drainage pipes instead of cement pipes and cast iron pipes, and have broad market prospects. Our company is the authoritative manufacturer of large diameter hollow wall winding pipe production line in China. It has strong technical advantages and rich experience in production and installation. The equipment is advanced in design, high-end configuration, reliable operation, long service life, the output of the same model is far higher than the level of the same industry, especially has rich experience in super large diameter models, and can meet the needs of large scale high-end customers at home and abroad. The performance index of Hollow wall winding pipe machinery has reached the international advanced level.