Call Us

+86-13780696467

Email Us

sales@qdcomrise.com

China pvc plastic pipe bend machine 6 piece Manufacturer, Supplier, Factory

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of pvc plastic pipe bend machine 6 piece,plastic pipe cutter machine,agricultural plastic pipe machine,plastic pipe extruder machine,machines for plastic profile and pipes, We've been devoted to offer professional purification technology and methods in your case!

pvc plastic pipe bend machine 6 piece, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

Hot Products

PP PE Sheet Extrusion Machine

China Comrise machinery is a professional supplier and manufacture for high quality PP PE sheet extrusion machines. Comrise offer a complete range of solutions for the production of high-quality sheets with multiple layers suitable for various applications, including packaging, construction, and more.Flexible Corrugated Hose Extrusion Machine for Cable Protection

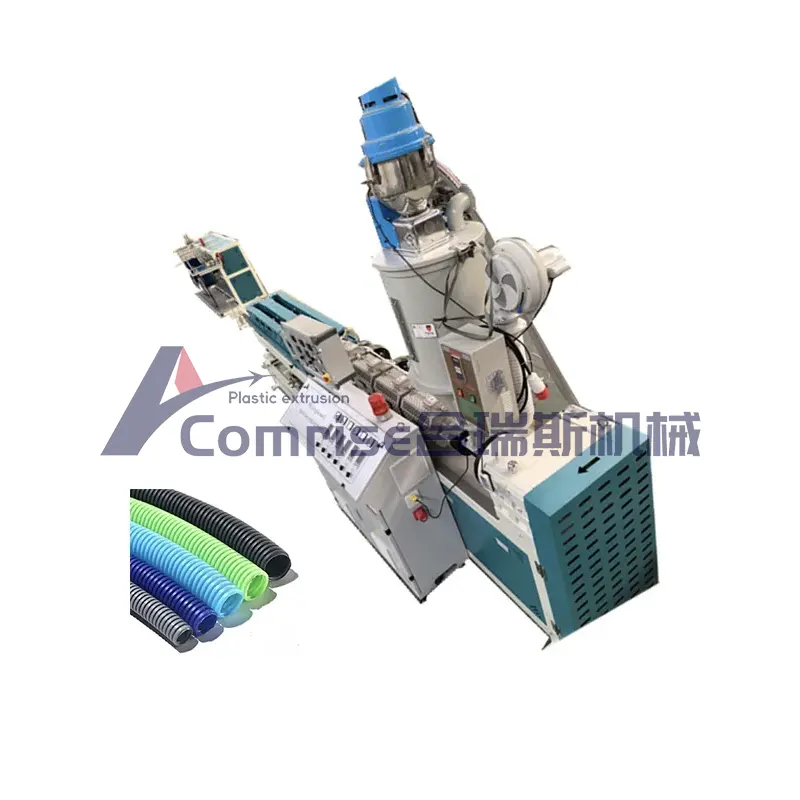

China factory comrise machinery has a range of flexible corrugated hose extrusion machine for cable protection that manufacture single wall corrugated pipes. These pipes provide efficient protection to cables and electrical wires while ensuring maximum safety. The flexible corrugated hose extrusion machine for cable protection supplied by Chinese manufacture Comrise Machinery are designed to produce pipes of different sizes and shapes, ensuring maximum flexibility.PVC Stone Marble Sheet Machine

PVC Imitation Marble Sheet Machine, exclusively offered by Comrise Machinery. With Comrise professional and leading technical team, they have developed a successful PVC Stone Marble Sheet Machine that produces high-quality imitation marble sheets.100mm Single Wall Corrugated Pipe Machine

Comrise Machinery offer a wide range of 100mm Single Wall Corrugated Pipe Machine for producing pipes in various materials such as PP, PE, PA, MPP, and PVC. Our 00mm Single Wall Corrugated Pipe machines are capable of producing high-quality pipes in different sizes and dimensions to meet the unique needs of our clients.300-1200mm PE Hollow Pipe Making Machine

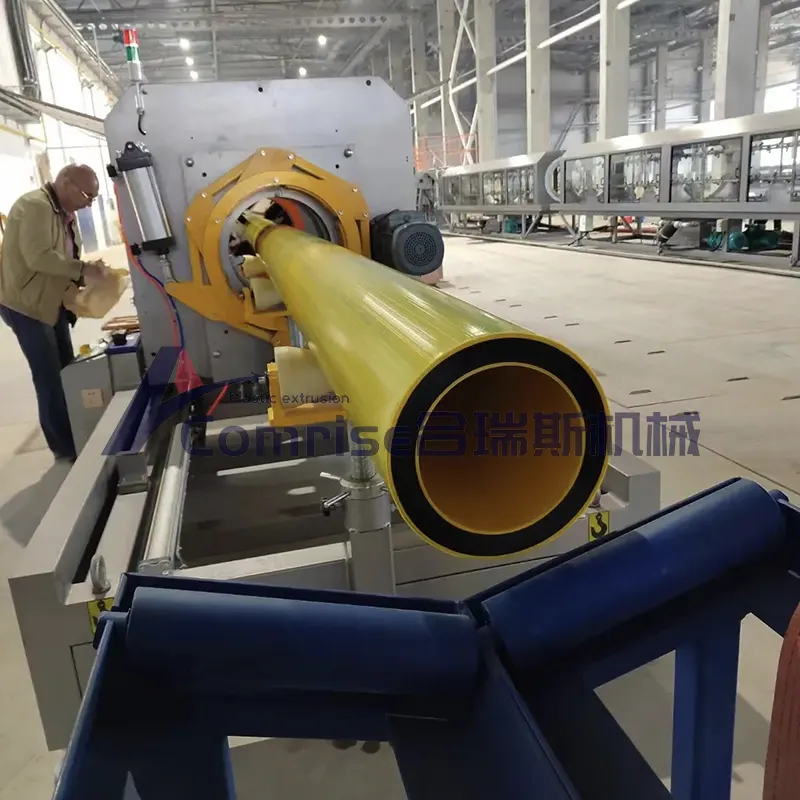

Comrise is a professional and high quality 300-1200mm PE Hollow Pipe Making Machine manufacturer and 300-1200mm PE Hollow Pipe Making Machine supplier in China with good price. COMRISE’s commitment to quality is evident in the numerous advantages that come with using its plastic pipe machines. These 300-1200mm PE Hollow Pipe Making Machine offer high production capacity, which translates to faster turnaround times and increased efficiency. 300-1200mm PE Hollow Pipe Making Machine are also very user-friendly, with easy-to-use controls that allow for quick adjustments and minimum errors. Additionally, COMRISE’s after-sale service is top-notch, with a team of experts on standby to provide you with technical assistance if needed.Pe Spiral Winding Pipe Machine

COMRISE specialize in providing advanced pe spiral winding pipe machine machinery for underground sewage construction or building usage. Comrise pe spiral winding pipe machine are used to create a variety of pipe types for different applications, such as hollow wall spiral winding, inner rib spiral winding, smooth wall winding, double plastic winding, and plastic insert steel winding. Comrise take pride in our expertise when it comes to larger diameter pipe machines, as it requires not only specialized machinery but also highly skilled professionals to operate them.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy