China Plastic Water Storage Tank Extruder Manufacturer, Supplier, Factory

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for Plastic Water Storage Tank Extruder,HDPE Hollow Wall Spiral Pipe Making Machine,Plastic Profiled Hollow Wall Winding Pipe Extruder,HDPE Plastic Hollow Wall Winding Pipe Machine,Plastic Water Septic Storage Tank Making Machine, we could solve our customer problems asap and do the profit for our customer. For those who need superior provider and excellent , pls choose us , thanks !

Plastic Water Storage Tank Extruder, We'll supply much better products and solutions with diversified designs and expert services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information be sure to feel free to contact us. We are looking forward to receiving your enquiries soon.

Hot Products

Composite Decking Profile Machine

Comrise Machinery is a professional manufacturer of PE WPC wood-plastic composite decking profile machines. We offer comprehensive solutions, including all processes from raw materials to finished products, to produce high-quality, environmentally friendly, and durable composite flooring. Comrise PE WPC wood-plastic composite decking profile machine use advanced technology to achieve high productivity and efficiency while keeping operating costs low. Comrise also provide comprehensive technical support and after-sales service, ensuring that our clients can operate our equipment with ease and minimize downtime. Comrsie PE WPC wood-plastic composite decking profile machines can be customized to meet the specific needs of our clients. Comrise are known for our high-quality products and services, ensuring the complete satisfaction of our clients. If you're searching for a reliable and efficient manufacturer of PE WPC wood-plastic composite decking profile machines, look no further than Comrise Machinery.50-160mm Pe Pipe Machine

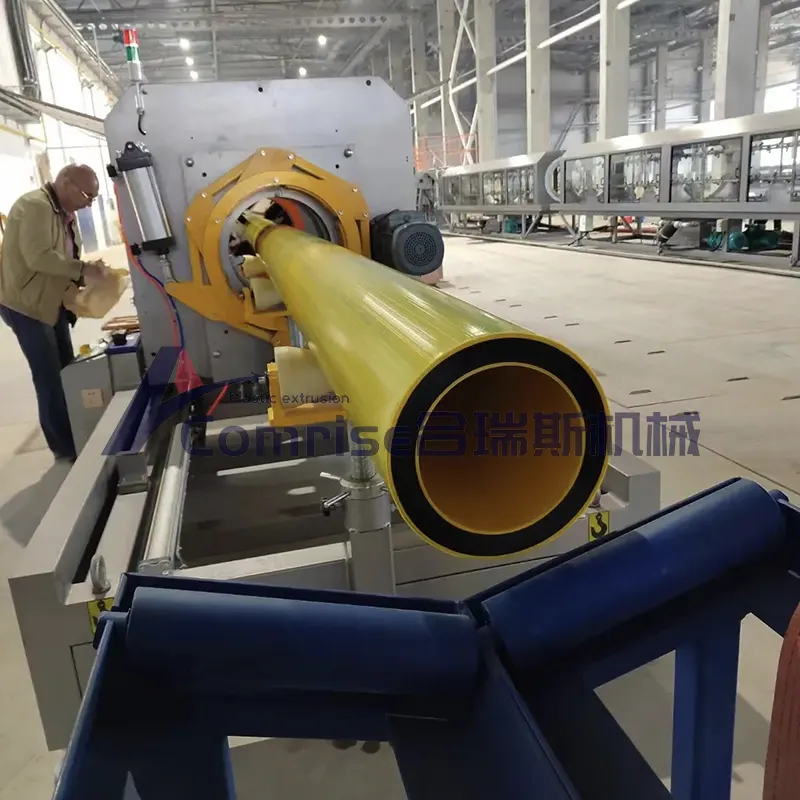

China Comrise's 50-160mm Pe Pipe Machine is the ultimate pe pipe production machine for any business. Its efficiency, speed, ease of maintenance, and stable running process make it a game-changer in the production of pe pipes. Invest in 50-160mm high efficiency Pe Pipe Machine today and take your business to the next level.PE Foam Insulation Pipe Making Machine

Comrise is a team of passionate professionals that strives to provide the industry with the best plastic pe foam insulation pipe making machines worldwide. China manufacture Comrise team comprises some of the most experienced engineers and designers dedicated to building reliable and efficient pe foam insulation pipe making machine. Comrise dedication to meeting and exceeding customer satisfaction has earned us a solid reputation in the plastic machinery manufacturing industry.50-250mm PVC Pipe Machine

Comrise Machinery is a leading professional manufacturer and supplier of 50-250mm PVC Pipe Machine in China, specialized in the production of 50-250mm PVC Pipe Machine. Comrise high quality 50-250mm PVC Pipe Machine including 65/132 or 80/156 or 92/188 conical double screw extruders, PVC pipe molds, vacuum water tanks, haul-off machines, and no dust cutter machines. Comrise cater to the needs of customers worldwide, and Comrise cheap price 50-250mm PVC Pipe Machine are known for their quality, reliability, and durability.Comrise advanced 50-250mm PVC Pipe Machine extruders are designed to offer superior performance and ensure the products' quality. They are equipped with Siemens PLC control systems, ensuring precise control and monitoring of the manufacturing process. Comrise newest 50-250mm PVC Pipe Machine pipe molds are made of high-quality steel, and Comrise use the latest 3D design technology to ensure that they meet the exact specifications of our clients. The vacuum water tanks are designed to ensure that the PVC pipes are cooled down and shaped correctly for different pipe diameters. Comrise easy operation 50-250mm PVC Pipe Machine the haul-off and no dust cutter machines are designed to meet the various production requirements of clients. They come with an automatic control system that ensures accuracy in cutting the pipes without causing dust. This feature ensures that Comrise high quality 50-250mm PVC Pipe Machine meet the industry's quality standards and are environmentally friendly. At Comrise Machinery, we offer our clients excellent services and technical support that ensure the low price 50-250mm PVC Pipe Machine are correctly installed, operated, and maintained. We understand that every client has unique needs, and we work closely with our clients to fulfill their requirements.PPR Pipe Extrusion Line

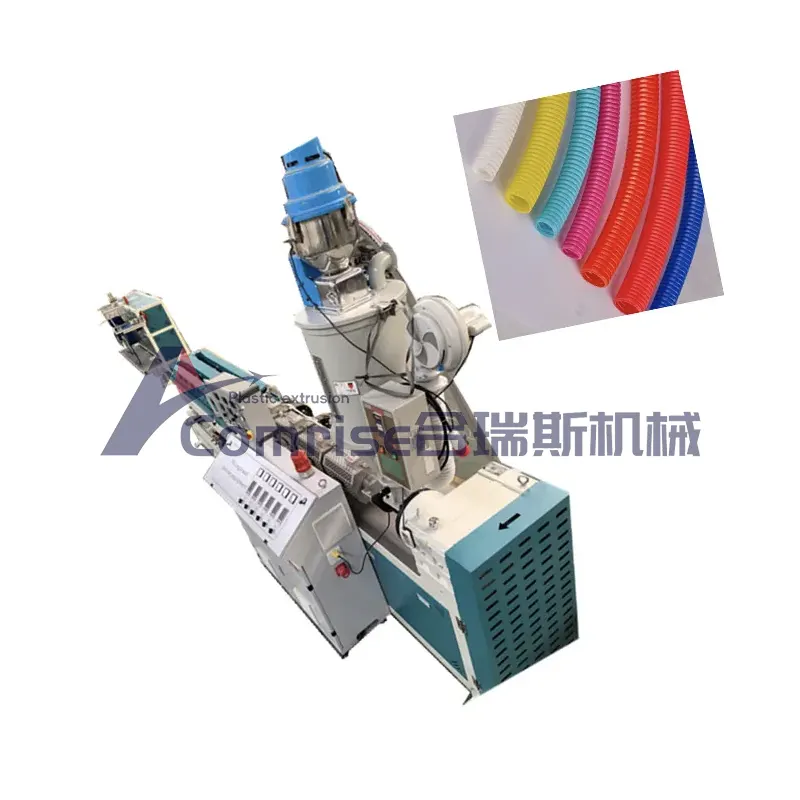

Comrise PPR pipe extrusion line is a specialized production system designed to manufacture polypropylene random copolymer (PPR) pipes, which are widely used in plumbing, heating, and industrial fluid transportation systems. The extrusion line is capable of producing pipes in various diameters (e.g., 16-63mm or 20-110mm) and structures (single-layer or multi-layer), depending on the application requirements.TPE Sheet Extrusion Line

TPE Sheet Extrusion Line is Comrise company that specializes in manufacturing sheet extrusion lines for the production of TPE sheets. Comrise machinery has been in operation for 20+ years and has gained a reputation for producing high-quality machines that are durable and efficient.