China HDPE Large Diameter Hollow Wall Winding Pipe Manufacturer, Supplier, Factory

Sticking for the belief of "Creating items of top of the range and creating buddies with people today from all over the world", we normally put the interest of shoppers in the first place for HDPE Large Diameter Hollow Wall Winding Pipe,HDPE Hollow wall spiral winding tank machines,HDPE hollow wall spiral winding pipe machines,PE Hollow Wall Winding Pipe Extrusion Line,HDPE Hollow Structure Wall Spiral Winding Sewage Pipe Machine, Welcome worldwide prospects to get in touch with us for company and long-term cooperation. We'll be your reliable partner and supplier.

HDPE Large Diameter Hollow Wall Winding Pipe, You can always find the products and solutions you need to have in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We're looking forward to work with you for a win-win situation.

Hot Products

pp hollow grid corrugated sheet making machine

Qingdao Comrise Machinery is professional China pp hollow grid corrugated sheet making machine Manufactures and China pp hollow grid corrugated sheet making machine suppliers. Comrise with mature technology and experience sale team and production team, who can provide you high quality and stable pp hollow grid corrugated sheet making machines with different specifications and applications.PVC steel wire pipe production machine

COMRISE PVC steel wire pipe production machine is designed specifically for manufacturing high-quality steel wire reinforced spiral corrugated pipes we manufacture it. The extrusion system includes a two-stage extrusion system, namely a steel coating extrusion system and a spiral forming extrusion system.chian top plastic machine factoryPVC Twin Pipe Machine

If you are in the market for a reliable and efficient PVC Twin Pipe Machine, Comrise Machinery is your perfect partner in China. Comrise high quality PVC Twin Pipe Machine come in different specifications and are designed to cater to a wide range of applications. Comrise offer excellent technical support and services to ensure that their advanced PVC Twin Pipe Machine operate optimally. Contact us today and experience the best PVC Twin Pipe Machine technology by sales@qdcomrise.com; whatsapp: +8613780696467.HDPE Pipe Machinery

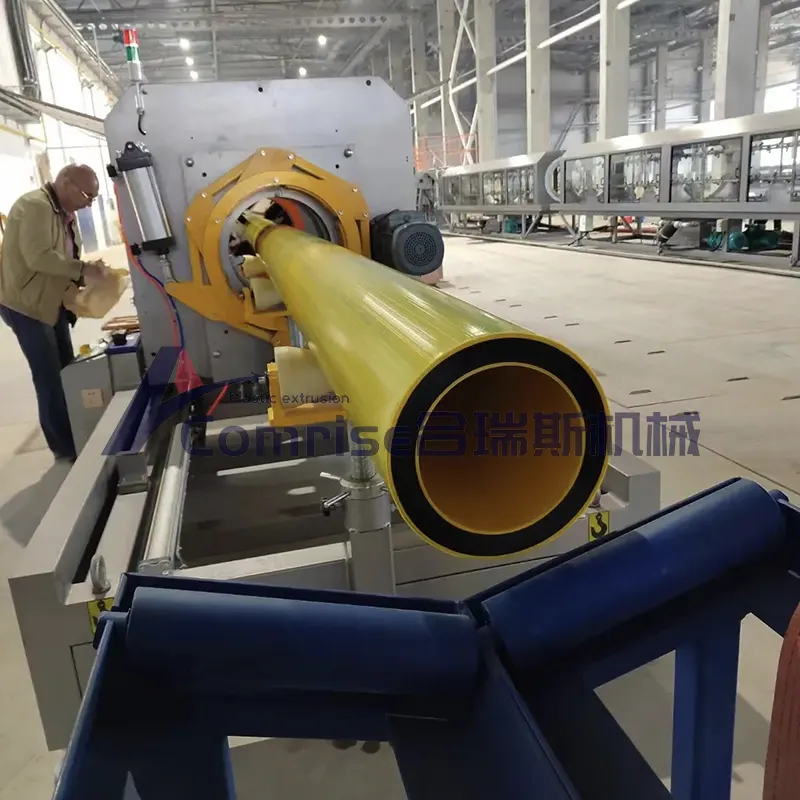

QINGDAO COMRISE MACHINERY main production line including high-efficiency PE water supply pipe production line, HDPE Pipe Machinery,PE large-diameter hollow-wall winding pipe production line, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line , the plastic coated corrugated pipe production line,PE black jacket insulation pipe production line and PE sheet/board production line, . HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.TPE Car Mat Extrusion Machine

Comrise machinery company is professional TPE Sheet Extrusion machine supplier in China who is dedicated to designing and building state-of-the-art sheet extrusion lines for the production of TPE sheets. Comrise are committed to providing their customers with the best possible service and support. Comrise team is highly skilled and experienced, and they are always striving to improve their TPE Car Mat Extrusion machines and processes. Whether you are in the automotive, packaging or medical industry, Comrise have the right TPE Car Mat Extrusion for you. Contact us today to learn more about what we can do for your business.cell+86 13780696467110-315mm Double Wall Corrugated Pipe Machine

Comrise Machinery is a professional manufacturer and supplier of single double wall corrugated pipe machines, conduit pipe machines, threading pipe machines, and various other machinery for the plastic pipe industry. Comrise machines are designed and built to produce high-quality 110-315mm Double Wall Corrugated Pipe Machine which made of PP, PE, PA, MPP, and PVC materials.