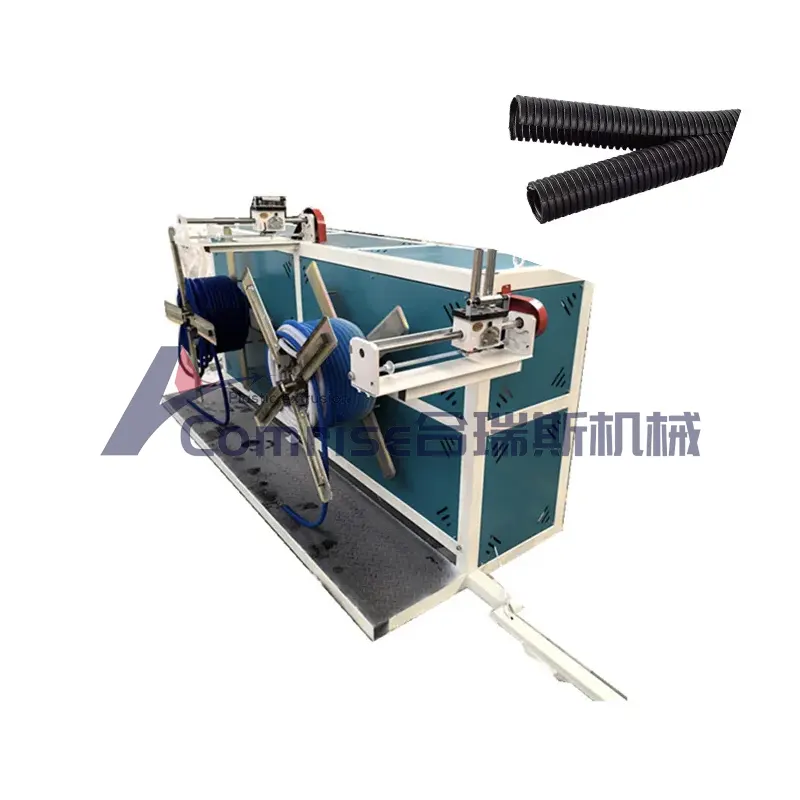

China fresh air double wall corrugated pipe extrusion production line Manufacturer, Supplier, Factory

To create much more benefit for shoppers is our enterprise philosophy; client growing is our working chase for fresh air double wall corrugated pipe extrusion production line,fresh air double wall corrugated pipe production line,fresh air double wall corrugated pipe extrusion line,fresh air double wall corrugated pipe machinne,fresh air double wall corrugated pipe extruder, We sincerely welcome mates from all over the globe to cooperate with us to the basis of long-term mutual added benefits.

fresh air double wall corrugated pipe extrusion production line, We warmly welcome your patronage and will serve our clients both at home and abroad with items of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Hot Products

150mm Double Wall Corrugated Pipe Production Line

Comrise Machinery is a professional China single wall corrugated pipe machine manufacture and 150mm Double Wall Corrugated Pipe Production Line supplier. The comrise single wall corrugated pipe machine can make pipe with different diameter from 4mm upto 200mm with different raw material like pp pe pvc pa and with different line speed for normal 8-15m/min design and 25-30m/min high speed design for customer choose. For the high quality 150mm Double Wall Corrugated Pipe Production Line also have two design for molds, iron material or aluminium material, iron material can save cost of machine, aluminum mold design which is lighter and speed faster, customer can choose as per detail requirements.Plastic Pe Pipe Production Line

China Comrise is a world-class manufacturer of plastic pe pipe production line. With its cutting-edge technology, global reach, and reliable service, the company has earned a well-deserved reputation as an industry leader. The HDPE PE pipe market is growing at an unprecedented pace, driven by the need for pipelines in various sectors, including water supply, gas distribution, and telecommunications. China Comrise has been at the forefront of this growth, providing high-quality plastic pe pipe production line that meet the changing needs of the industry.HDPE Pipe Machine Production Line

Cmrise factory HDPE Pipe Machine Production Line adopts the most advance technology of Europe. It is a new research achievement of energy - saving production lin, which is suitable for high speed extrusion of HDPE, PP and other polyolefin pipe. Compared with cornmon production line, the energy - saving effect reach on 35%, and the product efficiency increase more than 1 times, thus it is not only saving the cost of site and manpower, but also improving efficiency. 110-135mm hdpe pipe machine has nice appearance. higher automatical degree, production reliable and stable.Comrise is china top supplierPE Hard Permeable Pipe Machine

Comrise Machinery is a professional manufacturer in China that specializes in the production of PE hard Permeable Pipe Machine and other plastic extrusion machinery. Comrise has over 20 more years of experience in the plastics industry and has a team of skilled and experienced professionals. Comrise Machinery follows strict quality control measures to ensure that all PE hard Permeable Pipe Machine meet the highest standards of performance and reliability. The Comrise PE hard Permeable Pipe Machines are designed to produce high-quality permeable pipes made of polyethylene (PE) material, which are widely used in drainage and flood control systems.PP Hollow grid sheet production line

Qingdao Comrise Machinery is professional China PP Hollow grid sheet production line Manufactures and China PP Hollow grid sheet production line suppliers. Comrise with mature technology and experience sale team and production team, who can provide you high quality and stable PP Hollow grid sheet production lines with different specifications and applications.Co Extrusion HDPE Pipe Production Line

Comrise is a leading manufacture for ABC Three Layer Co Extrusion HDPE Pipe Production Line in China. Comrise specialized in the manufacturing of high-quality plastic extrusion equipment, including plastic pipe, sheet and profile equipment, as well as plastic winding pipe equipment. With over 20 years of experience in the industry, COMRISE has a mature and professional team of engineers and customer service representatives. Comrise company dedicate to provide top-of-the-line products and services, with strict quality control measures, We look forward to working with you to move the plastic extrusion equipment industry forward.