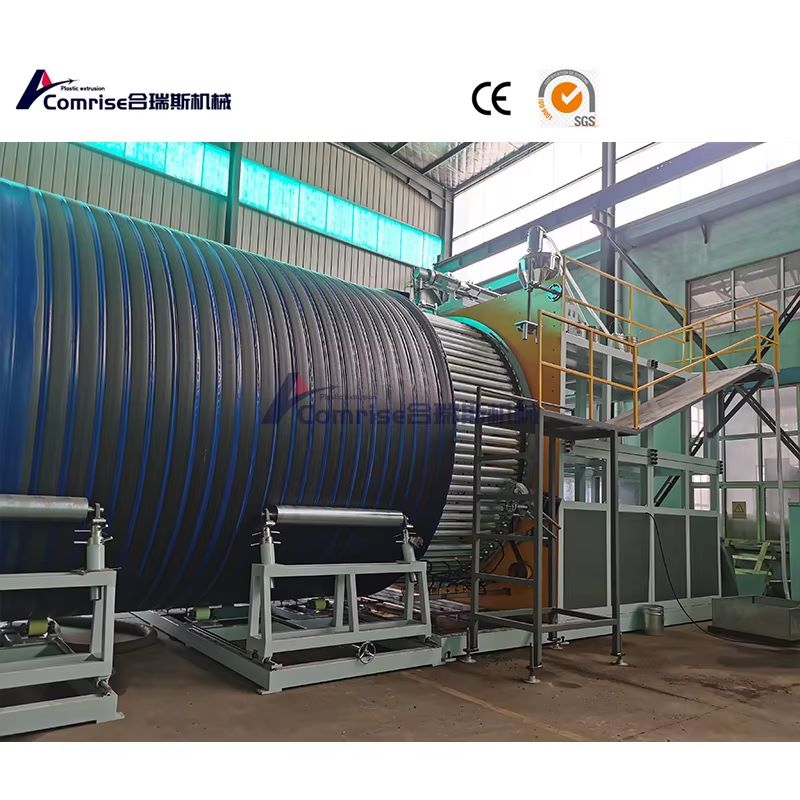

China 2400mm HDPE hollow wall winding pipe machine Manufacturer, Supplier, Factory

We believe that long time period partnership is a result of top of the range, value added services, rich expertise and personal contact for 2400mm HDPE hollow wall winding pipe machine,HDPE Hollow wall spiral winding tank machines,PE Hollow Wall Winding Pipe Extrusion Line,HDPE structured wall spiral winding pipe machine,HDPE Hollow Structure Wall Spiral Winding Sewage Pipe machine, We maintain timely delivery schedules, innovative designs, top quality and transparency for our buyers. Our moto should be to supply quality goods inside of stipulated time.

2400mm HDPE hollow wall winding pipe machine, We're sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

Hot Products

Drip Irrigation Pipe Machine Line

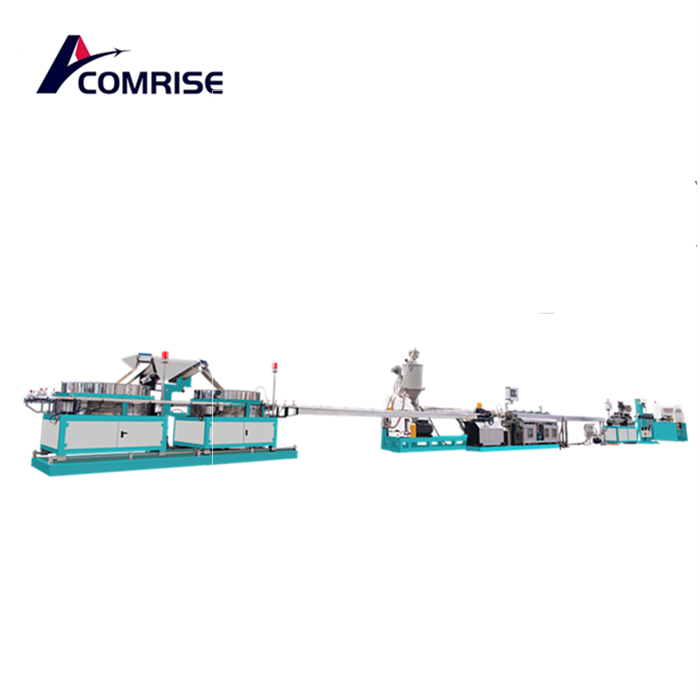

COMRISE High quality drip irrigation independent machinery Drip irrigation line we manufacture. comrise new production line has been launched, with better quality and faster speed. It can quickly replace droppers. Come in and take a look Standard output: Drip Irrigation Pipe Machine Line For each geometric shape of a given flat dropper, a kit can be used to replace the flat dropper output.china top factory machine supplierPP Pipe Manufacturing Machine

Comrise is China leading 315-630mm HDPE PP Pipe Manufacturing Machine supplier. We have been specialized in plastic extruder machinery field for 20+ years, and whole sale plastic pipe machine, plastic sheet machine, plastic board machine, plastic profile machine and auxiliary machine with good price and high quality. Our products have a good performance advantage and cover most of the European and Asian markets. We look forward to becoming your long-term business partner in China.75-250mm Hdpe Pipe Machine

Qingdao Comrise Machinery is a top manufacture for high speed 75-250mm Hdpe Pipe Machine and 75-250mm Hdpe Pipe Machine supplier in China. China 75-250mm Hdpe Pipe Machine are cheap, high quality, high speed, high efficient, big capacity, fast speed, easy to operate, PLC control and famous. And we have CE and other certificates. We are looking forward to you coming to buy our hot sale and best price 75-250mm Hdpe Pipe Machine from our factory which is in stock.Hollow wall winding pipe machine line

Comrise china fasctory supply HDPE hollow wall wrapped pipes have been successfully used as drainage pipes to replace cement pipes and cast iron pipes, and have broad market prospects. Our company is an authoritative manufacturer of large-diameter hollow wall winding pipe production lines in China,Hollow wall winding pipe machine line with strong technical advantages and rich experience in implementing production and installation. The equipment design is advanced, the configuration is high-end, the operation is reliable, the service life is long, and the output of the same model is far higher than the industry level. Especially for ultra large diameter models, we have rich experience and can meet the needs of large high-end customers at home and abroad. The performance indicators of the production line have reached the international leading level.Hdpe Pipe Machine

Comrise Machinery High-Density Polyethylene HDPE pipe machines are specialized equipment used to manufacture HDPE pipes, which are widely utilized in various industries due to their durability, flexibility, and resistance to corrosion and chemicals. These high quality Hdpe Pipe Machines are designed to extrude HDPE material into pipes of different diameters and thicknesses, catering to applications such as water supply, gas distribution, sewage systems, and industrial pipelines.Solid Wall Pipe Production Line

Comrise machinery is a manufacturer and supplier for Solid Wall Pipe Production Line, large diameter plastic spiral winding drainage and sewage pipe extruder machine,krah pipe extruder machine,Comrise focus on plastic Solid Wall Pipe Production Line more than 20 years.