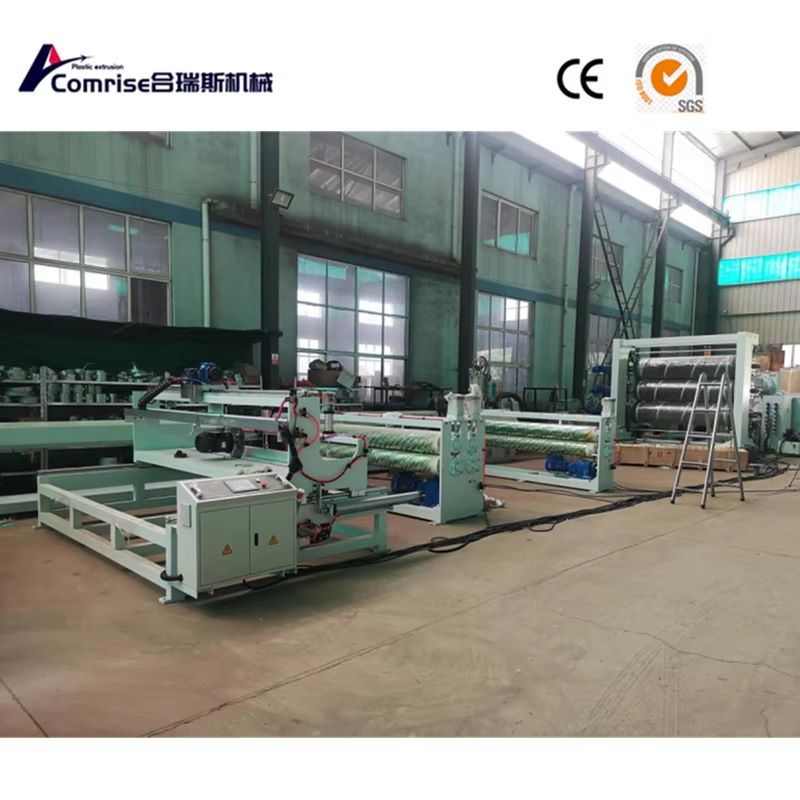

Thick Board Extrusion Production Line

Send Inquiry

Plastic Thick board machine

PP/PE/PVC thick plates have the characteristics of light weight, uniform thickness, smooth surface, good heat resistance, high mechanical strength, excellent chemical stability, good electrical insulation, and non toxicity. Widely used in chemical containers, electronic appliances, machinery, pharmaceuticals, and water treatment, etc

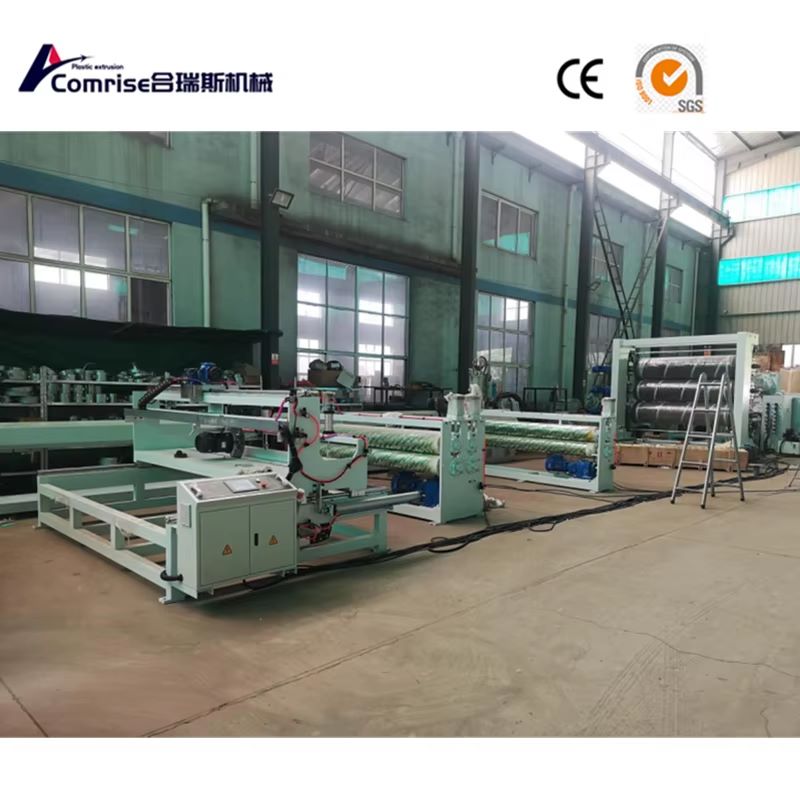

1. High capacity, approximately 400-550kg/h (for SJ130 single screw)

2. Energy saving: 20% more energy-efficient than ordinary machines we manufacture

3. The operation fully embodies the principles of ergonomics, which can make the functions more complete and the operation simpler.

4. Equipped with mold temperature control, stainless steel pump body, precise temperature control from room temperature to 300 ℃, temperature accuracy within ± 1 ℃, fully temperature controlled, fast heating, good temperature maintenance, long service life, saving time

1. The special screw design can effectively improve the plasticization rate, with a production capacity of up to 800 kg/h.

2. Thick Board Extrusion Production Line Optimized electrical design can achieve precise adjustment and automatic control and we manufacture the machine and we are china top factory and have high quality .

3. The production line adopts Siemens motors, ABB frequency converters, Schneider contactors, Siemens PLC control systems, and Siemens touch screens. Reliable electrical components and specially designed programs can ensure smooth machine operation, save power, and reduce waste.

|

Screw diameter |

120-180mm |

|

L/D |

33:1 |

|

Main motor power |

132-280kw |

|

Sheet thickness |

3-30mm |

|

Sheet width |

1200-3000mm |

|

Output |

600-1000kg/h |

|

Installed power |

200-580kw |

GET A QUOTATION NOW