PVC Pipe Machine Line

Send Inquiry

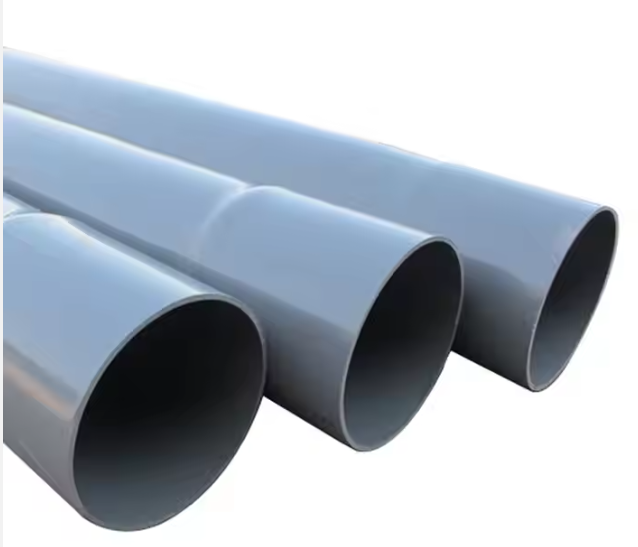

PVC pipe

1. It has good tensile and compressive strength, but its flexibility is not as good as other plastic pipes.

2. Low fluid resistance: The wall of PVC-U tube is very smooth, and the resistance to fluid is very small. Its roughness coefficient is only 0.009. Its water transport capacity is 20% higher than that of cast iron pipes with the same diameter, and 40% higher than that of concrete pipes.

3. Excellent corrosion resistance and chemical resistance: PVC-U pipes have excellent acid, alkali, and corrosion resistance, and are not affected by humid water and soil pH. No anti-corrosion treatment is required when laying pipelines.

4. Anti bite: PVC-U tubes are not a source of nutrients, so they will not be corroded by rodents. According to a test conducted by the Michigan National Health Foundation, mice do not bite PVC-U tubes.

5. Good water tightness: The installation of PVC-U pipes, whether through bonding or rubber ring connection, has good water tightness.

6. Performance testing: curing time, shrinkage rate, splitting strength, tensile performance, peel strength, thermal stability, shelf life, storage period, release of harmful substances.

Advantage co extrusion

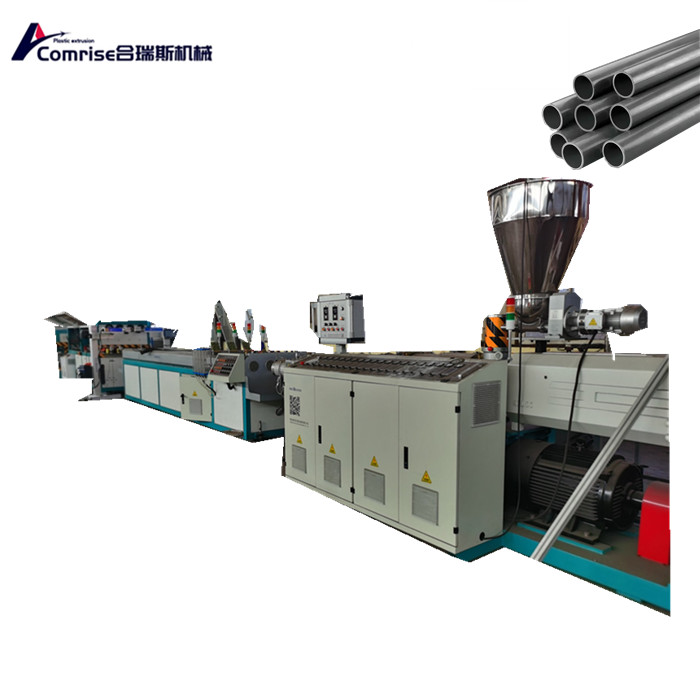

PVC pipe machine line

1. Better product performance: Double layer co extrusion technology can extrude and composite two different materials together, fully utilizing the advantages of the two different materials to improve product performance.

2. Simpler production process: Compared with traditional single-layer extrusion technology, double-layer co extrusion technology has a simpler and more energy-efficient production process.

4. Resource saving: Double layer co extrusion technology can simplify the storage and processing of different types of materials, reducing the waste of raw materials.

In summary, double-layer co extrusion technology has become the core technology of modern plastic manufacturing and is widely used in various industries. With the continuous advancement of science and technology, it is believed that double-layer co extrusion technology will have a broader development space

UPVC pipeline machine:

The PVC Pipe Machine Line is used to produce UPVC/PVC pipes with diameters ranging from 16 to 800 millimeters, which are used for electrical pipes, building drainage, sewage pipes, water supply pipes, well casing pipes, agricultural irrigation pipes, etc.

It mainly consists of a conical twin-screw extruder, a mold, a vacuum calibration tank, a traction machine, a cutting machine, a stacker crane, and an expansion machine.

By changing the Dorn or mold lip, it can produce several diameters or wall thicknesses on the same machine.

This production line is used to manufacture PVC pipes of different diameters and thicknesses according to your requirements. Our company has adopted advanced technology from Western Europe on this production line and launched our own SJSZ series extruder, which uses suitable molds and auxiliary machines to directly convert thermoplastic materials, especially polyvinyl chloride, into pipes. The host is SJSZ 65/132, SJSZ 51/105, and many other projects to get what you want. The extruder is derived from an a.C motor with a propeller, which can be infinitely adjusted. It is also equipped with overload protection and shutdown alarm system. The core of the screw and the exterior of the barrel are cooled by oil circulation, including vacuum exhaust and forced feeding.

GET A QUOTATION NOW