Products

- View as

PS Plastic Sheet Production Line/PS Blister Sheet Production Machine

PS Plastic Sheet Production Line/PS Blister Sheet Production Machine PP/PS single-layer sheet, PS co extruded dual color sheet, PP double-sided high transparency sheet and other sheets used in the vacuum packaging industry PP Stationery Sheet Production Line PP transparent sheet, frosted sheet (coarse sand, fine sand), two-color sheet and other sheets used in the stationery packaging industry.

Read MoreSend InquirySingle Wall Corrugated Pipe Production Line

The PVC and PE single wall corrugated pipe production line produced by Qingdao Comrise Machinery Co.,Ltd.This equipment consists of a plastic extruder,a single wall corrugated pipe extrusion mold,a corrugated forming device,a cutting machine,and a winding machine By configuring different extruders and extrusion molds,our single wall corrugated pipe production line can produce high-quality PVC single wall corrugated pipes with high wear resistance,high temperature resistance,and uniform corrugated forming characteristics during high-speed production.

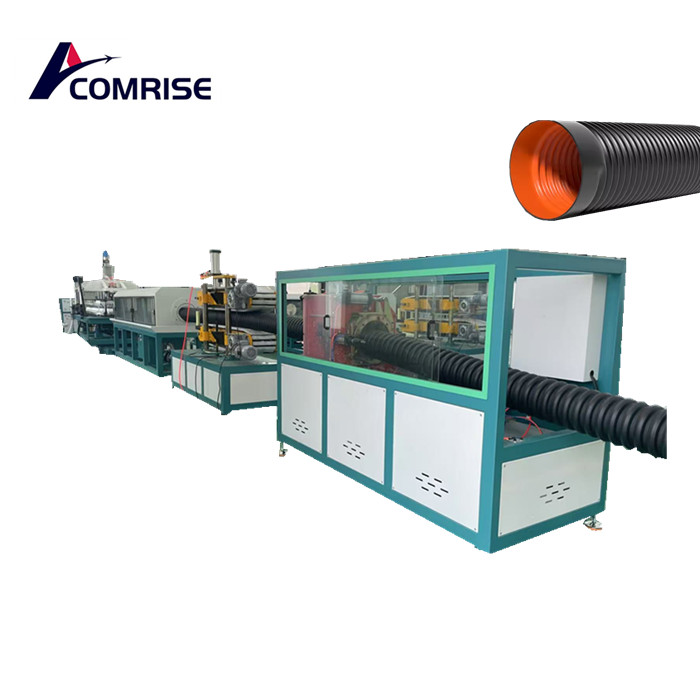

Read MoreSend InquiryLarge Diameter Double Wall Corrugated Pipe Machine

Large diameter double wall corrugated pipe machine is a mature product with advantages such as light weight, low cost, corrosion resistance, good ring stiffness, and good elasticity. Our company has been developing PE double wall corrugated pipe extrusion production line for more than 20 years. We have a complete series of double wall corrugated tube machines: horizontal, vertical, and shuttle. Our machines can process various materials, including HDPE, PP, PVC, etc.

Read MoreSend InquirySpecial Price for Hollow Wall Windding Pipe Machine

QINGDAO COMRISE MACHINERY CO., LTD is located in Qingdao, has 20 years experience in technological innovation, internal management and external market . We are a high-tech enterprise involved in the subject of polymer materials, integrating plastic machinery research and development, design and manufacturing, production management and technical services Today Special price for hollow wall windding pipe machine

Read MoreSend InquiryNew on PVC Pipe Machine

QINGDAO COMRISE MACHINERY main production line including high-efficiency PE water supply pipe production line, PE large-diameter hollow-wall winding pipe production line, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line , the plastic coated corrugated pipe production line,PE black jacket insulation pipe production line and PE sheet/board production line, . HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa. New on PVC pipe machine launched

Read MoreSend InquiryCorrugated Optic Duct Pipe Extrusion Machine

Advantages and functions of cluster tube and COD tube equipment: advantage: High production and processing efficiency. • Stable performance and reliable quality.Corrugated Optic Duct Pipe Extrusion Machine Function: Mainly used for the production and installation of pipeline systems, providing stable and reliable pipeline connections. Can meet the requirements of different engineering applications and ensure the smooth operation of pipelines. 1. The pipe is extruded by the first extruder and then enters the twisting machine, while the basket co extrusion mold forms the shape of the pipe. 2. The pipe material is mainly made of high-density PE.

Read MoreSend Inquiry