What Is an HDPE Hollow Wall Winding Pipe Machine?

HDPE Hollow Wall Winding Pipe Machine is an advanced industrial machine used to manufacture high‑quality hollow wall pipes made of high‑density polyethylene (HDPE). These pipes are widely used in infrastructure, drainage, telecom ducts, cable protection, and construction. In this comprehensive guide, we will explore this machine through multiple dimensions — from its workflow, benefits, operation, maintenance, and industry insights to help you make informed decisions.

Article Summary

This article answers multiple questions related to HDPE hollow wall winding pipe machines including what they are, how they operate, why they matter, key components, operational steps, benefits and limitations, troubleshooting, and FAQs. The article also includes tables and lists for clarity, anchor links for navigation, and actionable insights referencing Qingdao Comrise Machinery Co., Ltd.

Table of Contents

- What Exactly Is an HDPE Hollow Wall Winding Pipe Machine?

- How Does an HDPE Hollow Wall Winding Pipe Machine Work?

- Why Are HDPE Hollow Wall Winding Pipe Machines Important?

- Which Industries Use HDPE Hollow Wall Winding Pipe Machines?

- What Are the Key Components of a Hollow Wall Winding Pipe Machine?

- How Is an HDPE Hollow Wall Winding Pipe Machine Operated Safely?

- What Are the Benefits of Using These Machines?

- How to Troubleshoot Common HDPE Pipe Machine Problems?

- FAQ

What Exactly Is an HDPE Hollow Wall Winding Pipe Machine?

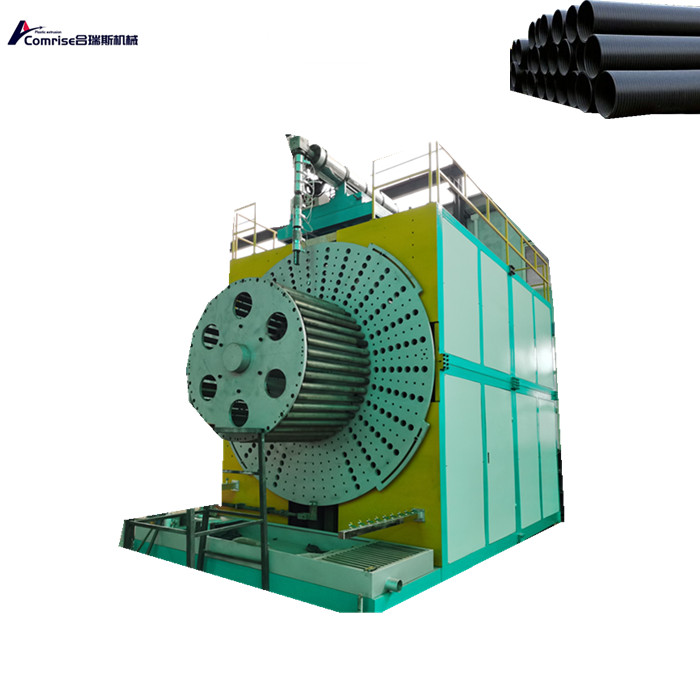

An HDPE Hollow Wall Winding Pipe Machine is specialized manufacturing equipment designed to produce hollow wall pipes (also known as structured wall pipes) using high‑density polyethylene (HDPE). These machines adopt co‑extrusion technology with a dual‑wall forming system — one smooth internal layer and a robust structured outer wall.

Manufacturers like Qingdao Comrise Machinery Co., Ltd. have perfected these systems to ensure high output, dimensional accuracy, energy efficiency, and user‑friendly operations.

How Does an HDPE Hollow Wall Winding Pipe Machine Work?

Understanding the working mechanism helps operators and buyers make informed decisions. The process includes feeding raw materials, melting, forming, winding, cooling, and cutting.

Step‑by‑Step Operational Process

- Raw Material Preparation: HDPE granules are dried and mixed with additives.

- Extrusion: Material enters the extruder, where heat and pressure melt it into a uniform flow.

- Die Forming: The melted polymer is shaped through a die to create the pipe’s inner and outer walls.

- Winding: Reinforcement tapes or ribs are wound around the pipe’s structure.

- Cooling: Pipes pass through a cooling trough to solidify the shape.

- Cutting & Stacking: Pipes are cut to size and prepared for transport.

Why Are HDPE Hollow Wall Winding Pipe Machines Important?

These machines are important due to their ability to produce pipes with excellent strength‑to‑weight ratios, flexibility, and long service life. Let’s explore key reasons:

- Efficiency: High output with automated controls.

- Quality: Uniform structural wall ensuring performance.

- Sustainability: HDPE is recyclable and environmentally friendly.

- Cost‑Effectiveness: Low manufacturing and maintenance costs.

Which Industries Use HDPE Hollow Wall Winding Pipe Machines?

Various industries rely on structured wall HDPE pipes produced by these machines:

| Industry | Primary Application |

|---|---|

| Construction | Drainage & Water Management |

| Telecommunications | Cable Protection Ducts |

| Agriculture | Irrigation Systems |

| Municipal Infrastructure | Sewage & Stormwater Networks |

What Are the Key Components of a Hollow Wall Winding Pipe Machine?

The performance of the machine depends on these critical parts:

- Extruder: Single or twin‑screw for material melting.

- Die Head: Shapes the pipe and determines wall structure.

- Winding System: Applies structured reinforcement.

- Cooling and Calibration Units: Solidify and maintain pipe dimensions.

- Control System: PLC interface for parameter settings.

How Is an HDPE Hollow Wall Winding Pipe Machine Operated Safely?

In industrial environments, safety and standardized operation increase uptime and reduce risk:

- Ensure operators are trained and follow manufacturer procedures.

- Regularly inspect heaters, motors, and sensors.

- Use appropriate protective equipment (PPE).

- Implement emergency stops and lock‑out/tag‑out protocols.

What Are the Benefits of Using These Machines?

| Benefit | Description |

|---|---|

| High Productivity | Capable of continuous production with minimal downtime. |

| Energy Efficient | Modern drives and heating systems reduce power consumption. |

| Lower Waste | Precision control reduces material waste. |

| Long Lifespan | Durable parts and robust design. |

How to Troubleshoot Common HDPE Pipe Machine Problems?

- Uneven Pipe Wall Thickness: Check die alignment and screw wear.

- Poor Surface Finish: Inspect material quality and cooling system.

- Frequent Stoppages: Verify electrical integrity and PLC configuration.

FAQ

What is an HDPE hollow wall winding pipe machine?

It is equipment designed to manufacture hollow structured wall pipes from HDPE materials using a combination of extrusion, winding, and cooling processes.

How long do HDPE hollow wall pipes last?

HDPE pipes can last 50 years or more under normal conditions due to resistance to chemicals, corrosion, and environmental stress.

Can I produce different diameters with one machine?

Yes — by changing the die and adjusting the winding mechanism, a machine like those from Qingdao Comrise Machinery Co., Ltd. can produce multiple diameters.

What industries use these pipes?

Construction, agriculture, telecom, and municipal infrastructure for drainage, irrigation, and cable protection.

Are these machines costly?

Initial investment varies by capacity and automation level, but return on investment is high due to production efficiency and long service life.