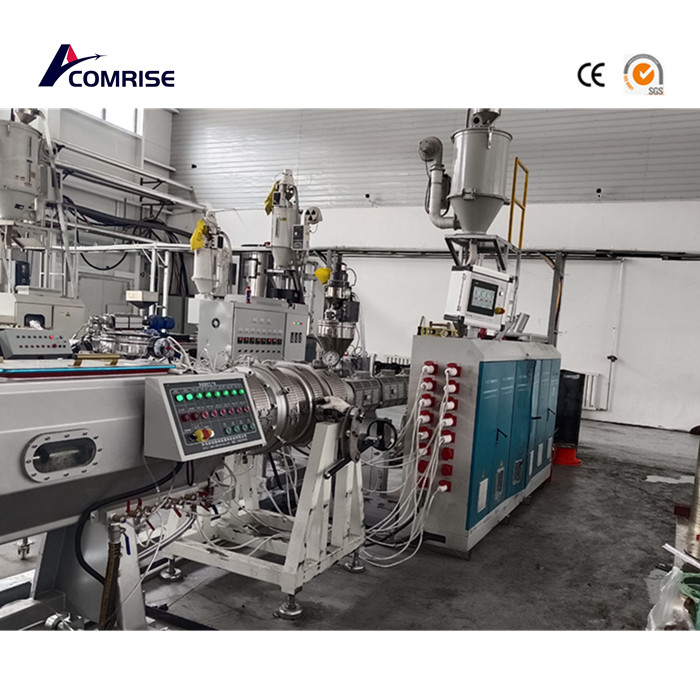

Three PE pipe machines have been installed at the customer's factory

2025-06-10

HDPE, PP, and PP-R pipes are vital across numerous sectors due to their excellent properties, including durability, chemical resistance, and long service life. You can learn more about the general benefits and applications of these versatile materials from reputable industry resources . Our versatile machines empower you to produce pipes for:

HDPE application: mainly used to transport the tap water we drink, water for irrigation of farmland, and gas.

PP application: used for industrial wastewater or liquids with chemicals. Some specific types of this hard plastic pipe can also be connected to cold and hot water at home.

PP-R application: it is dedicated to plumbing systems in homes and buildings, such as tap water pipes and heating pipes.

The pipe diameter range of 16-315 mm, coupled with the diversity of materials, covers a wide range of high-demand applications.

Achieve Superior Pipe Quality, Consistently Across MaterialsOur precision single-screw technology, coupled with high-quality die heads and robust calibration, delivers pipes with excellent dimensional accuracy, smooth surfaces, and consistent wall thickness.

This ensures your products meet or exceed stringent industry specifications, such as those outlined by international standards organizations like ISO for plastic piping systems

Features of Pipe Machiner:

1- 30m/min of maximum lineal extrusion speed, big capacity and low power consumption, and achieved multi- layers co extrusion with 1-5 layers.

2- The copper bush is more wear-resisting and prevent material leakage which can guarantee a stable running of extruder.

3- Material feed via spiral groove, efficient transmission and can effectively reduce back-pressure on extruder.

4- Unique design (barrier, shearing and mixing zone) guarantees a uniformed plasticizing effect, and can reduce the pressure on the screw which guarantees a high speed and stable output capacity.

5- High torque gear box has a smart figuration, compact construction, low noise, high carrying capacity, high transmission efficiency can assure long-time trouble-free operation;

6- PCA(pipe air cooling system) of die head largely increase the extrusion speed and decrease the cooling length of extrusion line, and improve quality of inner pipe surface;

7- Intelligent PLC controlling system with human-friendly interface make the operation easily and conveniently;

8- Chip-free cutter ensuing flat and smooth cutting surface of pipe.

The optimum spiral structure-feeding throat highly improves the output of extruder;

Accurate temperature control system ensures materials melting performance;

Unique screw design achieves better plasticizing and high-quality products;

Precisely designed gearbox with a high torsion guarantees stable running;

"H" shape frame to decrease vibrating of extruder;

Advanced PLC operation system realizes synchronization and automation;

Adopt automatic water temperature & level control and special independent filters on both vacuum and cooling tanks;

Offer stable haul-off unit with 2-12 caterpillars;

Provide saw & chip-free cutting options;

Low energy consumption, excellent performance, and easy maintenance.

GET A QUOTATION NOW