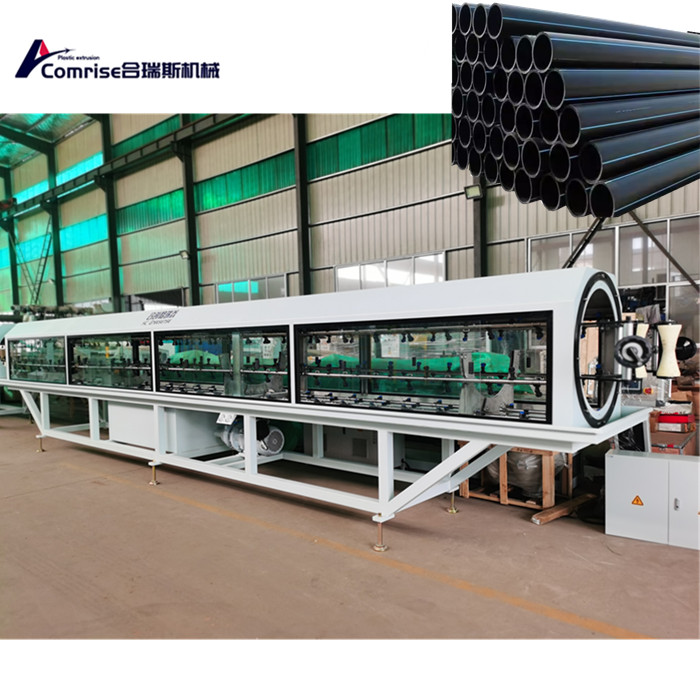

The 315-630mm machine is currently in production in our workshop

2025-05-13

Equipment composition:

Single screw extruder+co extrusion machine+pipe mold+vacuum sizing box+cooling spray box+six jaw crawler tractor+chip free cutting machine+flipping rack.

Advantages:

High output and stable operational performance.

PLC automatic control system and HMI touch screen control panel.

Mold temperature automatic control system.

● Meter weight system.

Adopting the most advanced spiral mold structure design.

The traction machine is driven by servo motors, with a wide speed range and good stability. Equipped with a winch, it is easier to pull pipes in the initial stage.

● Chip free cutting machine, suitable for PE pipes with different diameter ranges.

Reliable performance and high production efficiency.

Product Usage:

The 630mm HDPE pipe extrusion production line is a large-scale production equipment for HDPE pipes, which can supply the wastewater contained in the wastewater to solid waste that can be treated for pretreatment and cleaning.

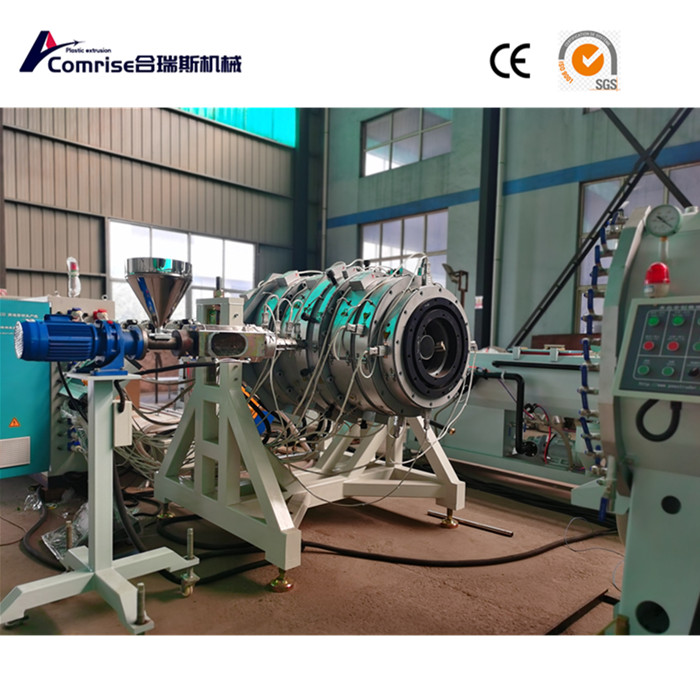

1. The production line uses our company's dedicated HDPE and PP pipe extruders. The screw adopts a barrier and mixing head structure, and the barrel adopts a new type of slotted barrel. The plasticization and mixing of small fruits are good, and the extrusion volume is large and very stable.

2. A spiral die designed for HDPE and PP large-diameter thick walled pipes, which has the characteristics of low melt temperature, good mixing performance, low mold cavity pressure, and stable production.

3. The proprietary technology for sizing and cooling system adopts water film lubrication and water ring cooling to meet the requirements of HDPE and PP materials, ensuring stable diameter and roundness for high-speed production of thick walled pipes.

4. A specially designed multi-stage vacuum sizing box that controls the vacuum degree, ensuring the dimensional stability and roundness of HDPE and PP pipes The extruder and tractor are controlled by imported brand speed controllers, which have good stability, high accuracy, and high reliability. A special high-pressure cooling system has been specially designed using an elliptical correction device and a multi-level, direct air cooling system to ensure the extrusion of large-diameter, high-pressure pipe level PE.

5. The tractor can be selected according to the size of the pipe. The speed control system of the six jaw tractor runs stably and reliably. The cutting machine is chip free cutting, computer-controlled, highly automated, and requires lifelong maintenance. Based on more than ten years of professional production experience, Lianshun Machinery has produced PE pipe extrusion production lines with a diameter range of 315-630mm, which are widely used in urban gas pipes and water supply pipes.

The PE pipe equipment is a spiral die designed for HDPE and PE large-diameter thick walled pipes. This die has the characteristics of low melt temperature, good mixing performance, low mold cavity pressure, and stable production. The operation and time of PE pipe equipment are programmed and controlled by PLC, with a good human-machine interface. All process parameters can be set and displayed through the touch screen. Can be equipped with a marking line extruder to produce pipes with colored markings that meet national standards.

The feeding machine is an automatic spiral feeding machine with fast feeding speed, saving labor, simple operation, and improving production efficiency. The extruder screw is supplied by a large manufacturer with guaranteed quality. Vacuum box vacuum shaping, good shaping effect, not easily deformed. The crawler tractor runs stably, and the cutting machine belongs to chip free fixed length cutting, which can cut to any length according to customer needs. The flipping table is made of stainless steel material, which is stable and reliable. The entire production line is basically fully automated, easy to learn, and easy to operate.