What Are the Main Applications of Pipes Made by an HDPE Spiral Pipe Machine

2025-12-10

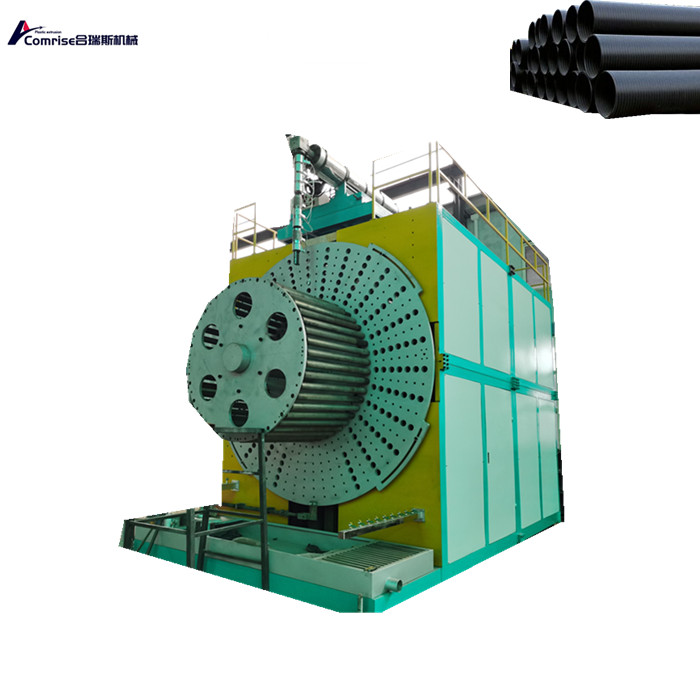

If you’ve spent two decades in infrastructure, water management, or industrial project planning like I have, you know the core challenge isn’t just moving material from point A to point B. It’s about finding a solution that stands the test of time, environment, and budget without constant maintenance headaches. For years, I’ve seen projects succeed or falter based on one critical choice: the piping system. Today, I want to share my perspective on a technology that has fundamentally reshined reliability in large-diameter piping—the HDPE Spiral Pipe Machine. Specifically, let’s explore the vast applications of the pipes it produces and why understanding this is crucial for your next project. At Comrise, we’ve dedicated ourselves to mastering this technology, providing not just machines but integrated solutions that bring durability and efficiency to life.

Why Should You Consider the Output of an HDPE Spiral Pipe Machine for Your Project?

The heart of the matter is performance. Pipes manufactured by a high-quality HDPE Spiral Pipe Machine are not your standard fittings. They are monolithic structures created through a sophisticated helical winding and fusion process. This results in pipes with exceptional ring stiffness and a seamless, joint-free structure over impressive lengths. The primary raw material, High-Density Polyethylene, brings inherent corrosion resistance, flexibility, and a leak-proof fusion jointing system to the table. When you combine this material with the spiral winding technique, you get a product that tackles numerous application-specific pain points I’ve encountered firsthand: soil settlement, chemical aggression, and the exorbitant cost of disruptive repairs.

What Are the Core Parameters That Define These Pipes?

Before diving into where they are used, let's look at the what. The specifications of pipes from an HDPE Spiral Pipe Machine are what grant them their versatility. Here are the key parameters we engineer for at Comrise:

-

Diameter Range: This is where the technology shines. Unlike many extrusion methods, spiral pipe machines can produce diameters from a modest 300mm all the way up to 3000mm and beyond, making them ideal for large-scale conveyance projects.

-

Wall Thickness & Structure: The wall is a calibrated structure, often with a smooth inner surface and a corrugated or structured outer wall for optimal strength-to-weight ratio. Thickness is precisely controlled based on the required ring stiffness (SN).

-

Ring Stiffness (SN): A critical measure of a pipe's ability to resist deformation under load. Common classes are SN4, SN8, SN16, and higher, allowing for deep burial even under heavy traffic loads.

-

Material Grade: We use premium, virgin HDPE resins with high MRS (Minimum Required Strength) ratings, ensuring long-term strength and stress crack resistance.

-

Length: Pipes can be produced in long coils or straight lengths, significantly reducing the number of joints in a pipeline system.

To visualize the typical product range, consider the following standard specification table:

| Parameter | Typical Range | Project Implication |

|---|---|---|

| Standard Diameter (mm) | 300, 400, 500, 600, 800, 1000, 1200, 1500, 2000, 2500, 3000 | Suits everything from municipal sewer mains to industrial process water conduits. |

| Ring Stiffness (SN) | SN4, SN8, SN16, SN32 | Select SN8 for standard road crossings; SN16 for deep burial or high-load areas. |

| Standard Length (m) | 6m or 12m straight lengths; longer on request | Fewer field joints mean faster installation and a dramatically lower risk of future leaks. |

| Pressure Rating (PN) | PN2.5, PN4, PN6 (Non-pressure to Medium) | Ideal for gravity flow and low-pressure applications like stormwater and sewers. |

Where Exactly Can Pipes from an HDPE Spiral Pipe Machine Be Deployed?

The applications are diverse, solving real-world problems across sectors. Let me walk you through the main arenas.

Is Stormwater and Sanitary Sewer Management a Prime Application?

Absolutely. This is one of the most common and critical uses. Municipalities and contractors face immense pressure from infiltration, exfiltration, and pipe collapse. The leak-free, chemically resistant nature of HDPE spiral-wound pipes directly combats these issues. Their flexibility allows them to withstand ground movement, a common cause of failure in rigid pipes. Using a Comrise HDPE Spiral Pipe Machine output means building a sewer or stormwater system designed for a 50-100 year service life with minimal intervention.

How Do They Perform in Industrial and Agricultural Water Management?

In my experience, industrial sites demand robustness. Whether it’s for process water, cooling water discharge, or even mild chemical effluent, these pipes resist abrasion and a wide range of chemicals. For agriculture, their large diameter is perfect for irrigation mains and drainage projects. The smooth interior prevents scaling and biofilm build-up, maintaining flow efficiency over time—a key cost-saver for pumping energy.

What Role Do They Play in Landfill and Mining Operations?

This is a testament to their durability. Landfill leachate collection and gas extraction require pipes that can handle aggressive substances and subsidence. Similarly, in mining, for tailings slurry or mine dewatering, the abrasion resistance is paramount. The pipes produced by a robust HDPE Spiral Pipe Machine are often the most cost-effective long-term solution in these harsh environments, outlasting alternatives that would require frequent replacement.

Can They Be Used for Protective Conduits and Casings?

Beyond fluid transport, their structural strength makes them excellent as protective conduits for power and fiber optic cables, especially in direct burial or directional drilling projects. They provide a durable, water-tight sleeve that safeguards critical infrastructure.

To help you match the pipe to the application, here’s a functional guide:

| Application Sector | Primary Function | Recommended Pipe Specs (Example) | Key Benefit Realized |

|---|---|---|---|

| Municipal Sewer (Gravity) | Sanitary & Stormwater Main Lines | DN1200, SN16, 12m length | Zero infiltration/exfiltration, handles deep burial loads. |

| Industrial Outfall | Chemical or Thermal Discharge Lines | DN800, PN4, Chemical Resistant HDPE | Corrosion resistance, maintains integrity under thermal stress. |

| Agricultural Drainage | Subsurface Drainage, Irrigation Mains | DN600, SN8, Perforated options | Long, continuous runs for efficient land drainage. |

| Landfill Engineering | Leachate Collection, Gas Venting | DN1000, SN16, UV-stabilized | Withstands subsidence and aggressive leachate chemistry. |

| Telecom Protection | Fiber Optic Cable Conduit | DN200, SN8, Smooth Bore | Provides a water-tight, crush-resistant pathway for cables. |

Frequently Asked Questions About the HDPE Spiral Pipe Machine

In my twenty years, the same insightful questions arise from engineers and project managers. Let’s address three of the most pertinent FAQs.

What is the maximum production speed of a Comrise HDPE Spiral Pipe Machine, and what factors influence it?

Production speed is not a single number but a function of pipe diameter and wall structure. For a standard DN1000mm pipe with SN8 stiffness, a modern Comrise machine can produce approximately 2-3 meters per minute. The key factors are the extruder output (kg/hour), the winding head complexity, and the cooling cycle efficiency. Our engineers optimize the entire line for balanced output, ensuring consistent quality at sustainable speeds.

How does the jointing system work for pipes made by an HDPE Spiral Pipe Machine, and is it reliable?

This is the cornerstone of the system's success. Pipes are joined using butt fusion or extrusion welding, creating a homogenous, seamless connection that is as strong as the pipe itself. The process involves heating the pipe ends to a precise temperature and fusing them together under controlled pressure. When performed correctly by trained technicians—a process we emphasize at Comrise—the resulting joint is 100% leak-proof and fully structural, eliminating the weakest link in traditional pipelining.

Can an HDPE Spiral Pipe Machine use recycled HDPE material?

This is a nuanced question. While the machine's mechanism can process certain types of recycled material, the consistency and quality of the recycled HDPE are paramount. For critical applications demanding long-term pressure rating and stress crack resistance, we strongly recommend using a high percentage of virgin HDPE resin. For non-pressure, lower-specification applications, a controlled blend may be possible. Our technical team at Comrise can advise on optimal material selection based on your specific project requirements and lifecycle goals.

How Do You Make the Right Choice for Your Specific Needs?

Choosing the right piping solution is a strategic decision. It’s about total cost of ownership, not just initial invoice price. The pipes created by a well-engineered HDPE Spiral Pipe Machine represent a forward-thinking investment. They address the core pains of maintenance, durability, and installation efficiency that I’ve seen burden projects over decades.

The versatility in diameter, the assurance of leak-free fusion joints, and the resilience against environmental and chemical challenges make it a compelling choice across countless applications. From protecting our cities from sewer overflows to ensuring the smooth operation of an industrial plant, the technology proves its worth daily.

Your project deserves this level of reliability. If you’re planning a drainage, sewer, industrial, or protective conduit project, I invite you to look closer at what the HDPE Spiral Pipe Machine technology, particularly the integrated solutions we offer at Comrise, can achieve for you.

Have a specific application challenge in mind? Let's discuss how our expertise and technology can provide your solution. Contact us today for a detailed consultation and technical specifications tailored to your project parameters.