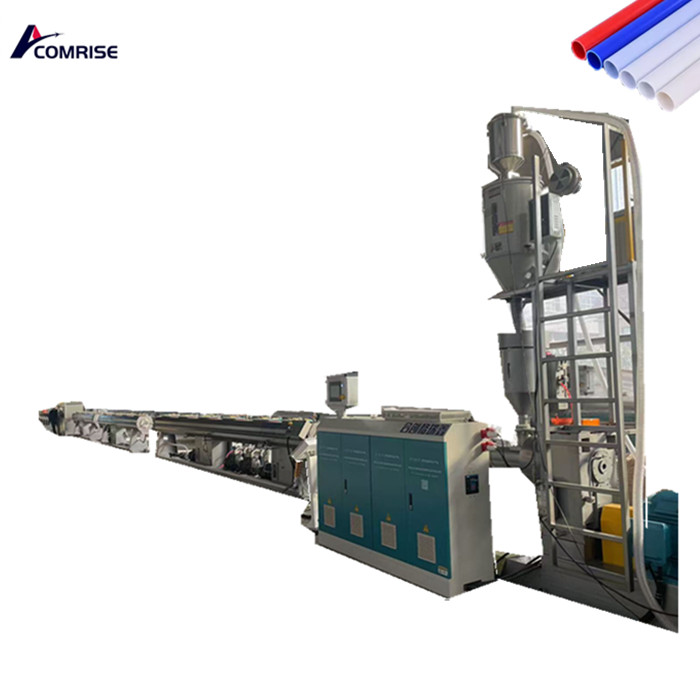

High speed HDPE pipe production line

2025-03-12

production line

Raw material+masterbatch → mixing → vacuum feeding → material drying → single screw extruder → basket co extrusion die → calibrator → spray vacuum calibration tank → spray cooling water tank → belt hauling → single screw glue extruder → winding machine → winding roller molding → water cooler → pipe rack → finished product inspection and packaging

Main advantages

1.This type of pipeline has many advantages, such as light corrosion resistance, easy fixation, and long service life.

2. Pipelines are widely used in highways, municipal buildings, apartments, etc.

Application description of polyethylene pipe extrusion production line:

This extrusion production line can be used for the production of PE pipes of different diameters, with excellent rigidity and flexibility, heat resistance, aging resistance, high mechanical strength, environmental stress cracking resistance, creep deformation resistance, thermal connection, and so on. Therefore, this pipeline production line is the preferred choice for gas, water, and agricultural irrigation pipeline systems between urban and rural areas.

Characteristics of Polyethylene Pipe Extrusion Production Line:·

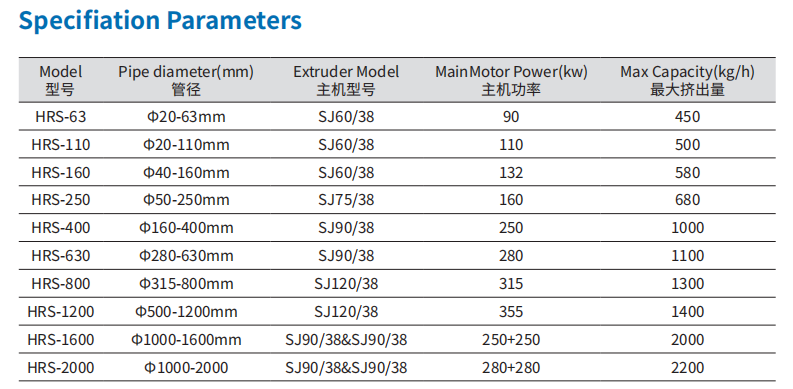

Capacity: Single screw extruder, suitable for processing high-capacity PE resin, with a maximum capacity of 1000 kg/h. Diameter: from 16 to 800 mm. Adopting reasonable design and absorbing safe production technology, it has obtained CE and ISO certificates

Final product

Price discounts welcome inquiries

GET A QUOTATION NOW